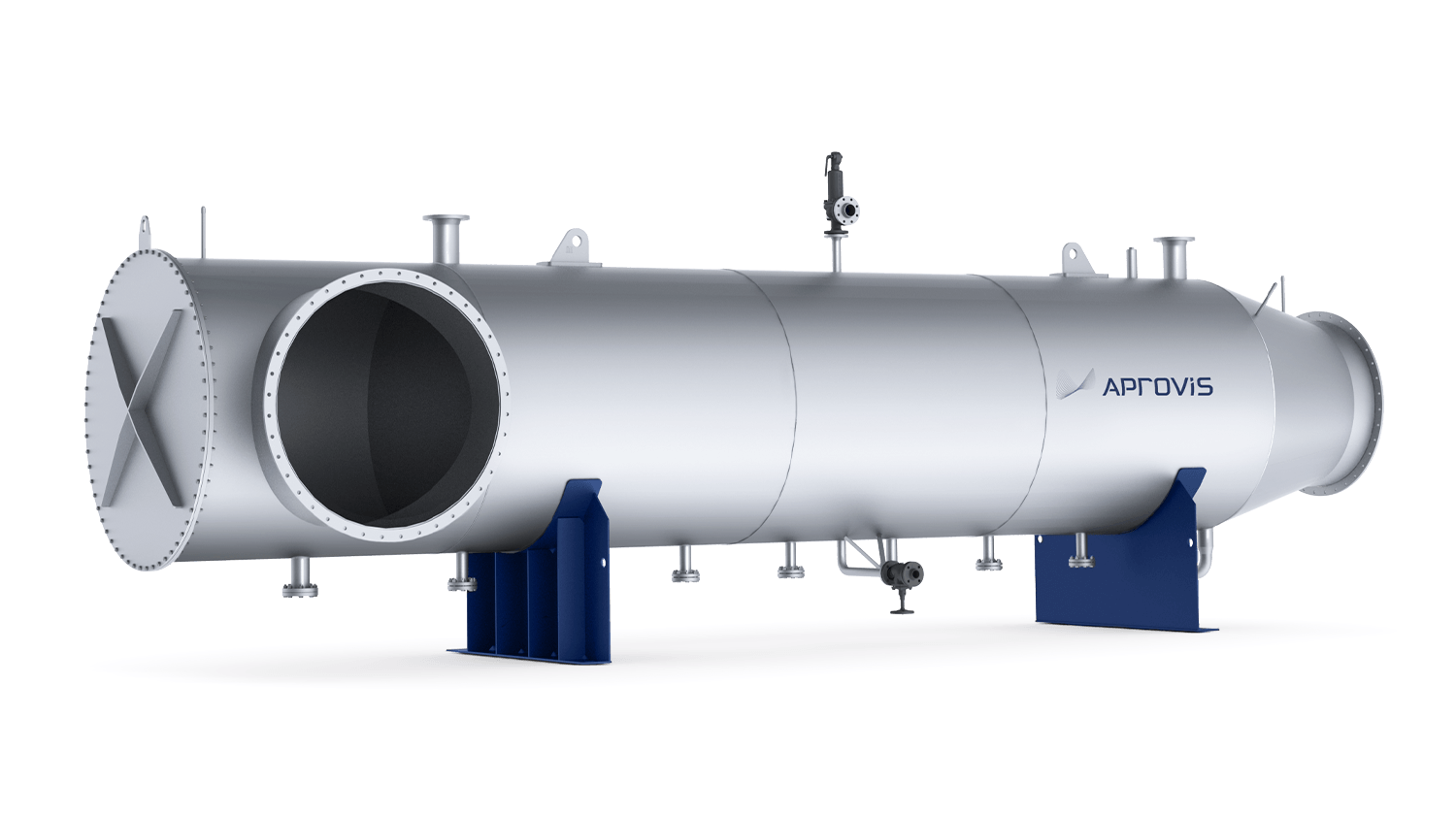

Exhaust gas heat exchangers

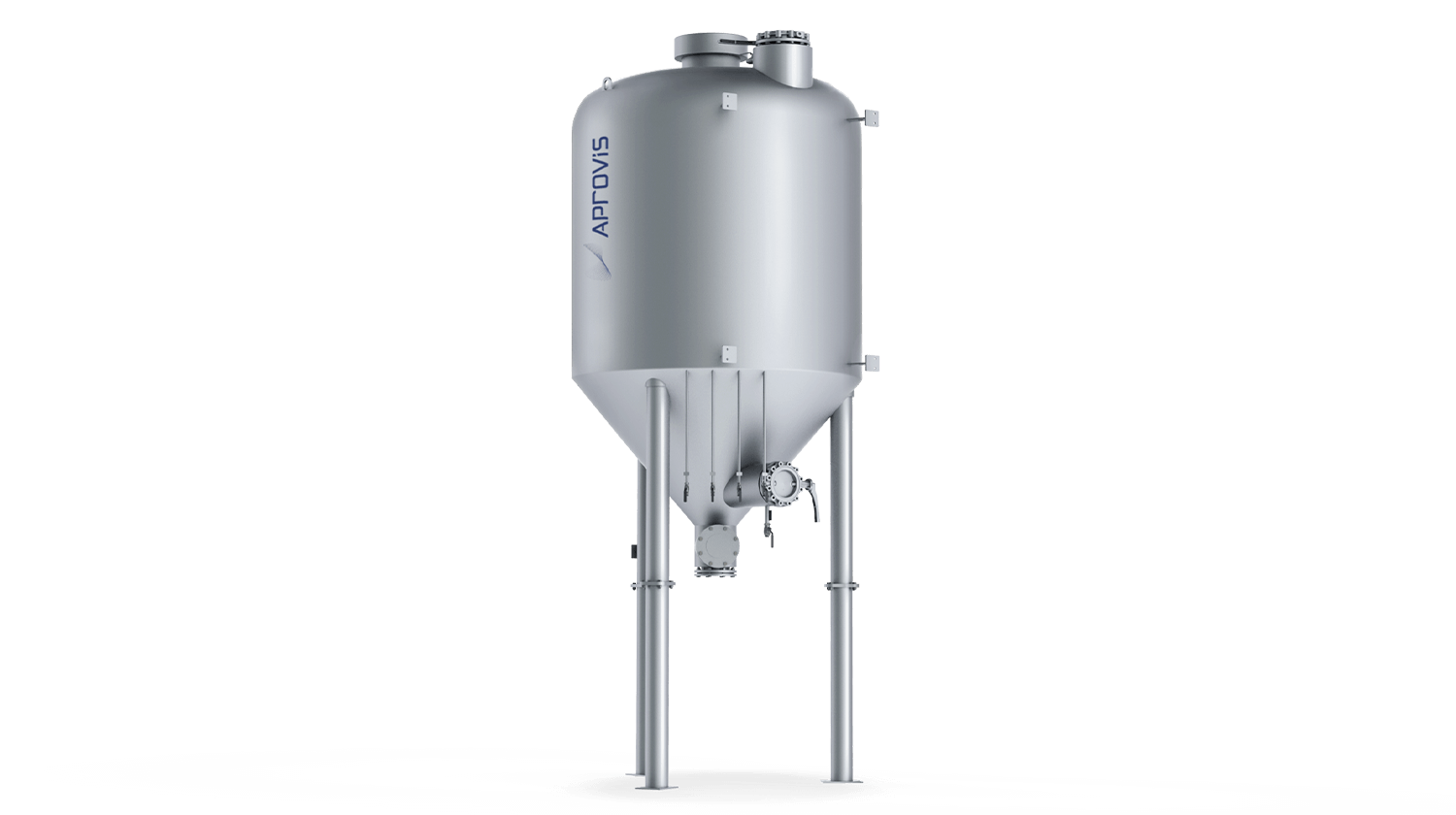

APROVIS exhaust gas heat exchangers

Peak performance for efficient use of waste heat

The cheapest energy is energy that is only captured in existing systems to make it usable, instead of having to produce it afresh elsewhere. And the better the components you use to do this, the greater the savings in terms of resources and costs. APROVIS is a professional and high-performance company operating in the field of exhaust gas heat exchangers. For more than two decades, the company has operated more than 20,000 plants worldwide, constantly advancing technology, expertise and efficiency. Our mission is to achieve ‘Better Performance’ – day in, day out. We work on this with every new idea and every product improvement, and with every component that leaves our production facilities. And we’re also there for you after delivery.

What you can expect from APROVIS exhaust gas heat exchangers:

- Efficient hot water generation in combined heat and power plants

- Heating of thermal oil as an energy source

- Individual solutions and compact designs

- All the main components for the exhaust gas section and gas treatment are combined under one roof: proprietary products developed in-house

- Cost-saving and reliable operation of the systems

- Maximum functionality, safety and service

- Temperature ranges: up to 600°C on the exhaust gas side or up to more than 1,000°C in the high-temperature range

- Certifications: PED 2014/68/EU, ASME Code, EAC

- Can be used in all plants with exhaust gases from hydrogen, natural gas, biogas, sewage gas and special gases, plus diesel and other liquid fuels

- Geared to international standards and directives

Individual components or a complete solution – customised completely to your needs

We develop custom-made solutions made up of individual or multiple components depending on your requirements. Each project represents a reliable partnership and exclusive support – from the quotation process to maintenance. That makes all the difference.

Exhaust gas heat exchangers – available for all fuels imaginable

Engines for combined heat and power plants are operated with different fuels, including hydrogen, natural gas, biogas, sewage gas and special gases, plus diesel and other liquid fuels. The suitable material for the exhaust gas heat exchanger’s chambers, tubes and tube sheets depends on the exhaust gas in question and the process used. The decision for the ideal product is made based on our many years of experience.

Potential applications of APROVIS exhaust gas heat exchangers

- As mini CHP units and for CHP plants up to 1,000 kWel

- For biogas / natural gas applications up to capacities of 10 MWel

- For large co-generation plants, e.g. municipal utilities > 10 MWel

- For gas turbines (lightweight design)

Exhaust gas heat exchangers as condensers for greater energy recovery

As a condenser, the exhaust gas heat exchanger ensures that more energy can be recovered from the exhaust gas. This particularly applies to the latent heat of the gaseous water vapour released during condensation. This method is suitable when the useful temperature level is low.

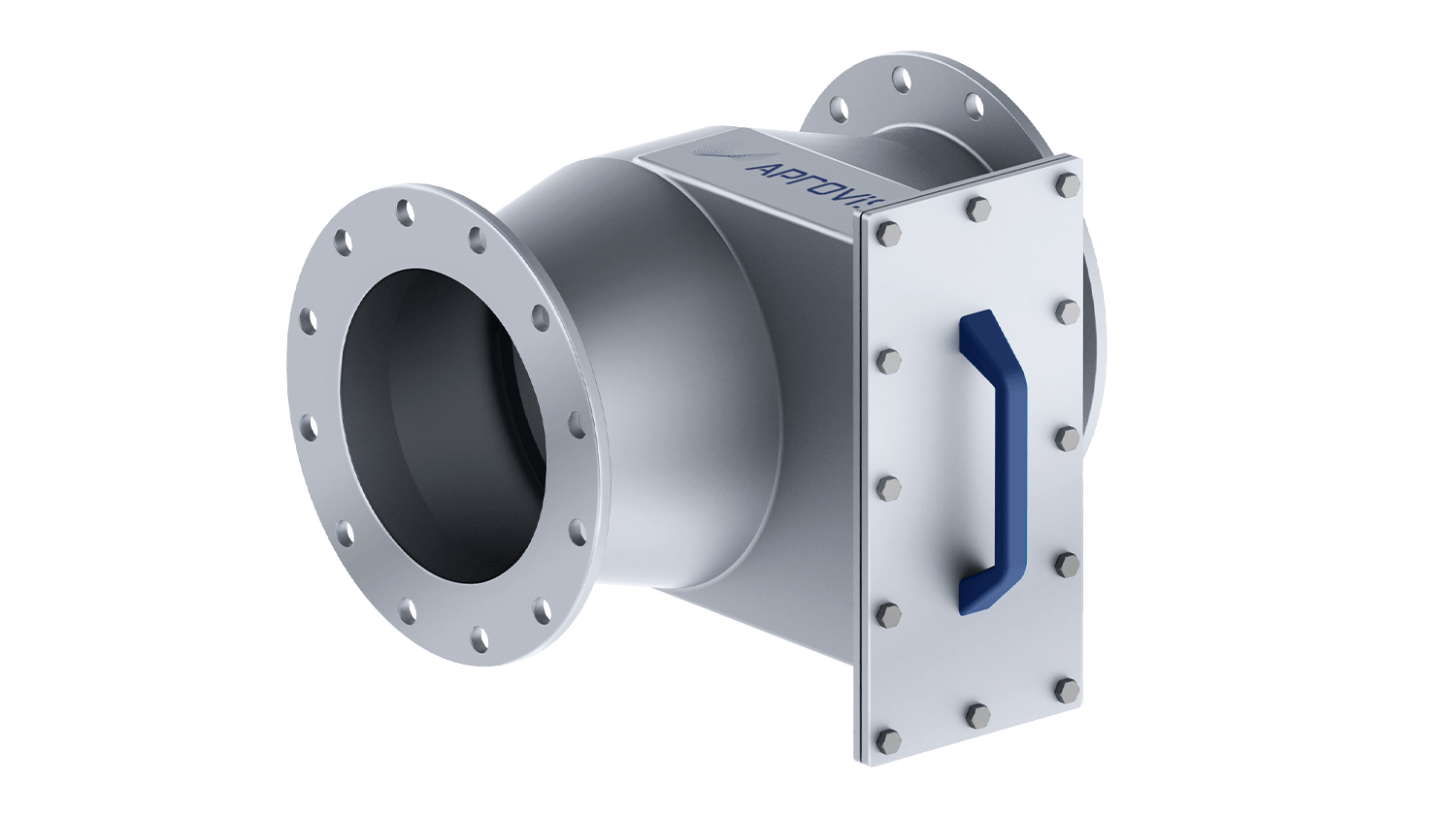

Smart bypass solutions depending on current requirements

A combined heat and power plant generates electricity via the generator and heat from the exhaust gas. If the exhaust heat is not required, the bypass directs the exhaust gas past the exhaust gas heat exchanger, and electricity continues to be produced during this process.

International guidelines and safety standards

The exhaust gas heat exchanger is a pressure vessel that must meet the requirements for the maximum permitted temperature and pressure values. These guidelines are country-specific and are taken into account accordingly by APROVIS. On request, we supply the exhaust gas heat exchanger with the prescribed safety equipment or in accordance with your defined safety equipment requirements. Our exhaust gas heat exchangers are approved in accordance with the European Pressure Equipment Directive (PED 2014/68/EU). If required, acceptance is also possible according to the ASME Code or EAC (Eurasian Customs Union). So pressure vessels can also be operated without any problems on the North American and Eurasian markets.

Additional highlights and functions of the exhaust gas heat exchangers from APROVIS:

- Additional insulation: APROVIS insulates the exhaust gas heat exchanger for the operator as needed. So no heat is lost and contact with the surface is safe.

- Heat use: On request, APROVIS combines the water side of the exhaust gas heat exchanger with the coolant side of the engine to form a single unit for heat use. This is done using valves, pumps and plate heat exchangers.

- Cleaning included: In the case of highly polluting exhaust gases, clean-in-process systems from APROVIS enable cleaning during operation. The enhanced efficiency increases the heat output, while less time and effort is required for servicing and costs are cut. If an exhaust gas heat exchanger has to be thoroughly cleaned, this incurs costs for cleaning and additional downtime caused by shutdown of the combined heat and power plant.

The exhaust gas heat exchanger as an efficient modular system with useful extensions:

When combined with other components such as silencers and catalytic converters (SCR cat, oxi-cat, three-way cat), the exhaust gas section can be significantly optimised. APROVIS supplies all the components (designed to be cost- or installation space-optimised depending on requirements) for this purpose. The individual components are coordinated so that the pressure drop per product is optimally used.

Another important operation-related advantage is that APROVIS remains the contact for its products throughout their entire service life.

What are your requirements?

Talk to our competent contacts and discover the advantages and possibilities for your application. We analyse, advise and supply swift and suitable solutions. We look forward to hearing from you.