Steam generators

APROVIS steam generators

Effective exhaust gas utilisation with smart control

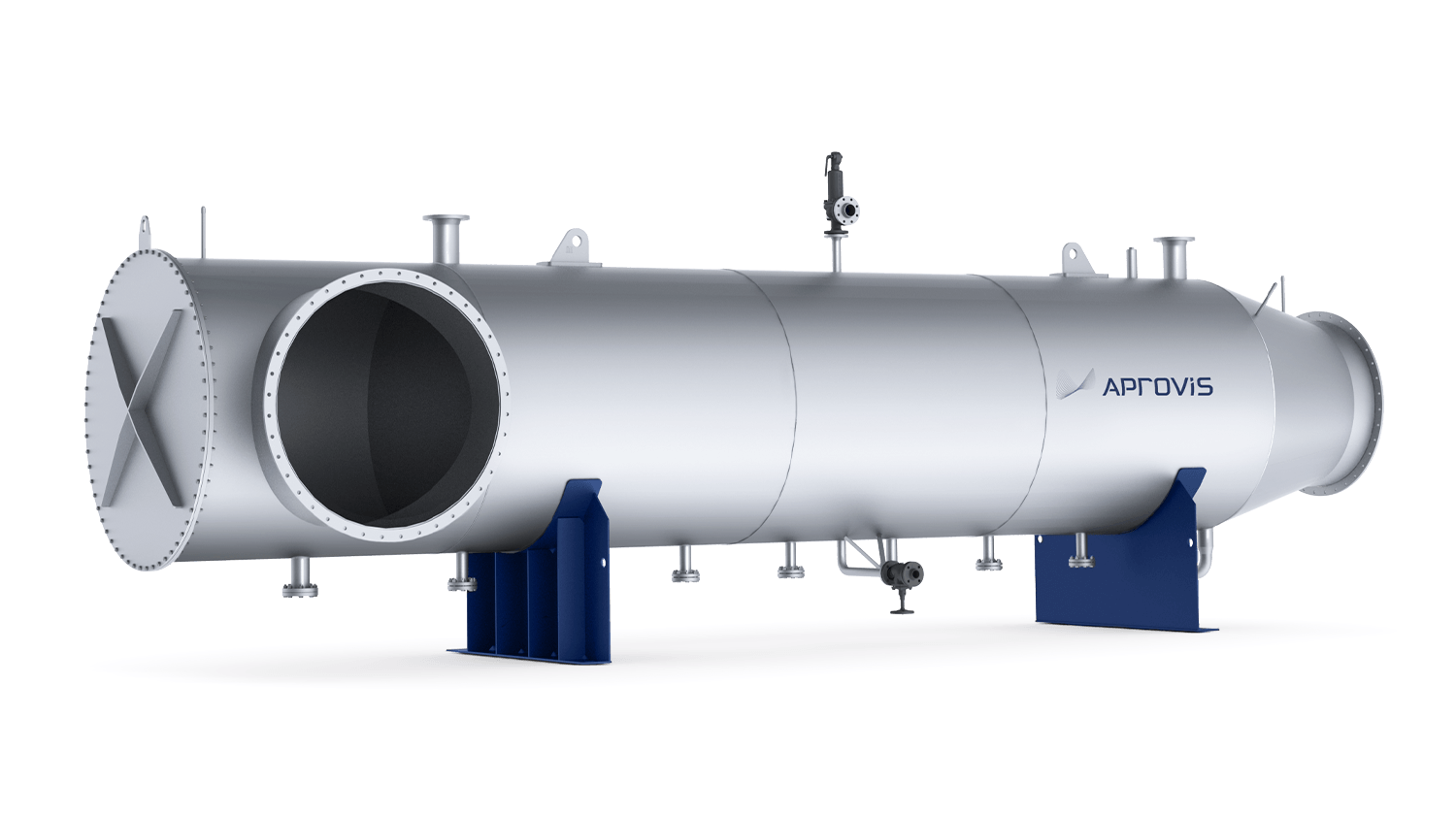

Steam generators from APROVIS use the energy from combined heat and power plants’ exhaust gas to generate steam. As

steam generator systems, they are energy efficient in operation and can be put to universal use. The range for saturated or superheated steam extends from 1 to 25 bar overpressure, while the capacity is between 100 and 25,000 kg of generated steam per hour. Control with the APROVIS Controlling System (ACS) also allows digitally supported fine-tuning, remote maintenance and remote commissioning. APROVIS demonstrates its expertise as an experienced OEM supplier for well-known engine manufacturers and for complete steam generator systems for combined heat and power plants, both nationally and internationally.

What you can expect from APROVIS steam generators:

- Efficient steam generation in combined heat and power plants

- Cost-saving and reliable operation of the systems

- Maximum functionality, safety and service

- Performance areas: 1 to 25 baro, 100 to 25,000 kg/h

- Certifications: PED 2014/68/EU, ASME Code, EAC

- Can be used in all plants with exhaust gases from hydrogen, natural gas, biogas, sewage gas and special gases, plus diesel and other liquid fuels

- Geared to international standards and directives

- Single, double or triple version for operation with one, two or three engines with completely separate exhaust gas sections

- The APROVIS Controlling System (ACS) is individually adapted to each project and is delivered in the required language

- Access to the ACS using a modem enables easy fine-tuning of the system or remote maintenance for swift support if and when discrepancies occur during operation

Custom-made complete solutions

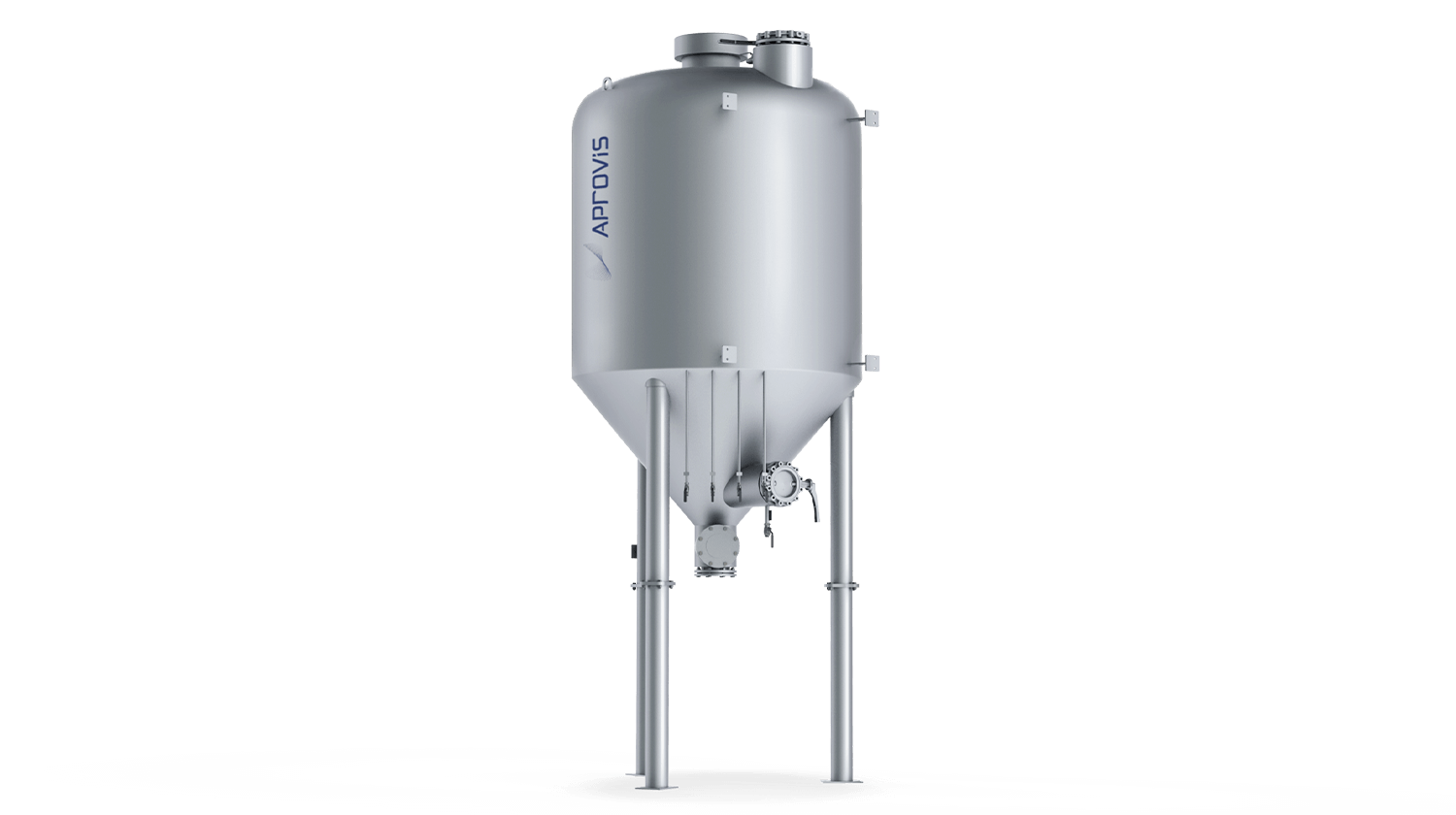

APROVIS’s steam generator systems are ready for connection and complement one another within precisely matched components. The main boiler body with prescribed safety technology forms the foundation. Economisers, bypass solutions and a pump unit are added, as is modern and convenient control and regulation technology. This wide-ranging scope of delivery guarantees custom-made applications and offers safe, fault-free and low-maintenance plant operation.

Potential applications of APROVIS steam generators

APROVIS’s steam generators are used in the following industries, to name but a few examples:

- Food processing, beverage production, textile industry, pharmaceuticals, paper production, chemical industry

APROVIS’s steam generators can be operated with exhaust gases from a variety of sources, the most common of which include:

- Exhaust gases from engine-operated CHP units, gas turbines, industrial processes with waste heat

Steam generators with economisers and exhaust gas heat exchangers save energy

The economiser preheats the feed water and cools the exhaust gas below the saturated steam temperature. This enables better use of the energy in the exhaust gas, which considerably improves the energy balance and significantly increases the amount of steam. The remaining residual energy in the exhaust gas can additionally be used in an exhaust gas heat exchanger.

Steam superheater to meet the highest requirements

The superheater raises the temperature above the saturated steam temperature for steam transport or in applications where superheated steam is required, such as in steam turbines.

Additional highlights and functions of the steam generators from APROVIS:

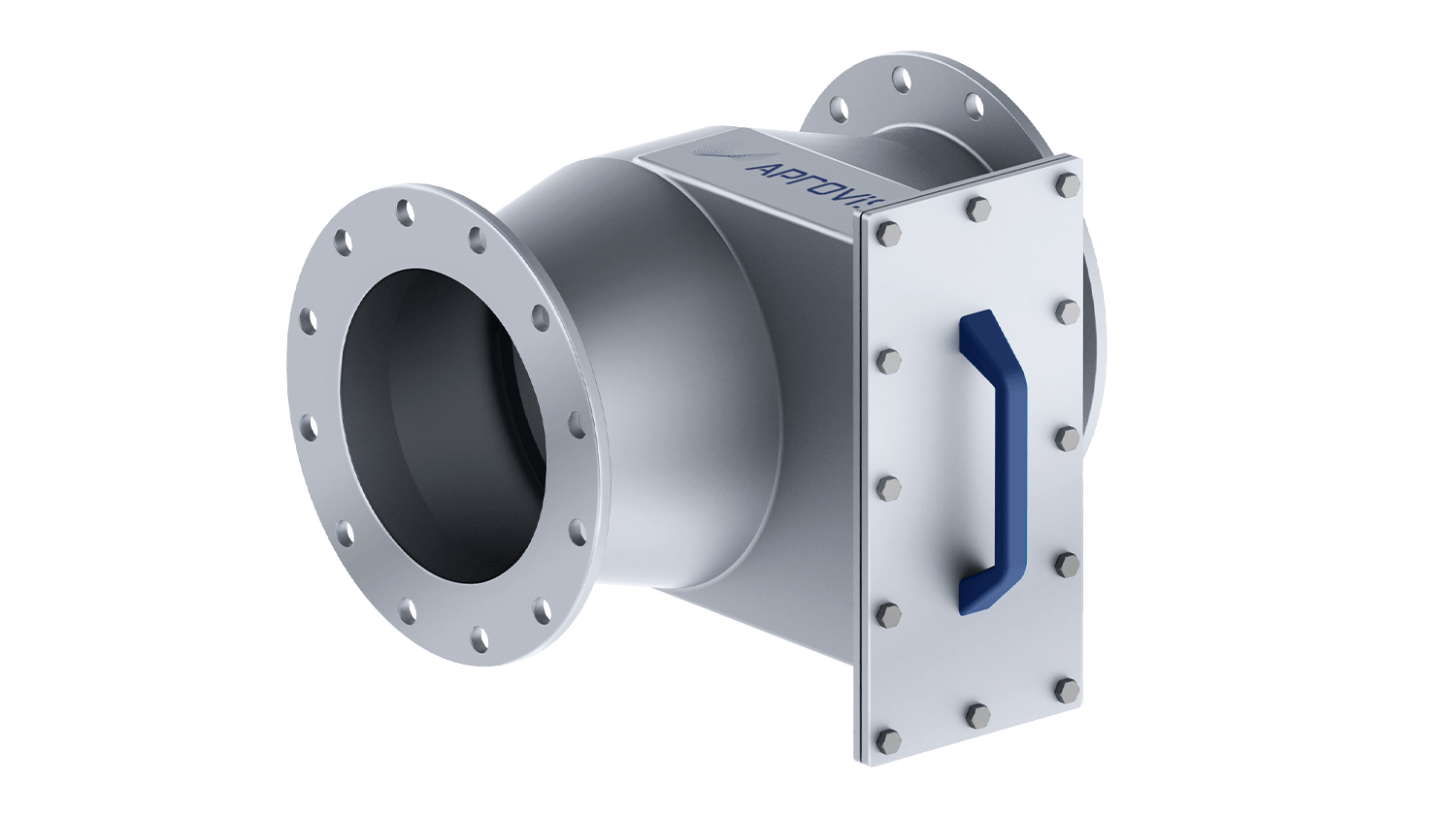

- Bypass solutions: An APROVIS bypass directs the exhaust gas past the steam generator. This prevents the pressure in the boiler from being exceeded and the engine can continue to run without any interruptions. This option is very important, especially if steam withdrawal fluctuates.

- Insulation: APROVIS insulates the steam generator for the operator. No heat is lost and contact with the surface is safe.

- Wiring: The safety technology on the steam generator is already wired to the APROVIS control box on delivery. This saves time and prevents potential troubleshooting on site.

- Pump unit: The standard version of the APROVIS pump unit is redundant and designed with inlet pressure monitoring. Stop valves are also provided to permit pump changeover during operation.

- Blow-down vessel: In the APROVIS blow-down vessel, desalted or blow-down boiler water is cooled to such an extent that it can be discharged into the sewage water system.

- Feed water treatment: On request, APROVIS supplies complete feed water treatment with softening, reverse osmosis and full degassing.

This prevents deposits, coatings and corrosion. - Steam quantity measurement: APROVIS supplies a steam quantity meter and integrates it into the APROVIS Controlling System (ACS) to verify the steam quantity provided to third parties.

Convenient operation with state-of-the-art technology

APROVIS offers the steam generator complete with a control box for customer-friendly plant control. The Basic, Classic and Premium variants are available to choose from. From the Classic variant upwards, regulation is conveniently carried out using a touch panel. APROVIS uses its proprietary software (APROVIS Controlling System (ACS)) and enables digitally supported remote maintenance and remote commissioning. Communication links (field bus systems) transmit the data from the steam generator controller to the combined heat and power plant’s main controller. A version with a safety PLC meets the necessary safety-related requirements and is recommended if the steam generator is integrated into a separate system.

Steam generator systems benefit from optional add-ons

When combined with other components such as exhaust gas heat exchangers, silencers and catalytic converters, the exhaust gas section can be individually optimised. APROVIS supplies all the components (designed to be cost- or installation space-optimised depending on requirements) for this purpose. APROVIS steam generator systems are also available in containers for installation outdoors. The service technicians are available worldwide to carry out commissioning and maintenance work.

International guidelines and safety standards

The steam generator is a pressure vessel. We ensure that country-specific requirements are met during project planning and production. On request, we supply the steam generator with the prescribed safety equipment or in accordance with your defined safety equipment requirements. All the safety technology is already wired with the APROVIS control box on delivery. Our steam generators are approved in accordance with the European Pressure Equipment Directive (PED 2014/68/EU). If required, acceptance is also possible according to the ASME Code or EAC (Eurasian Customs Union). So pressure vessels can also be operated without any problems on the North American and Eurasian markets.

Touchpanel ACS – APROVIS Control System

- All the actual values are displayed

- Intuitive operability and clear design

- Multi-touch, particularly good during trend zooming operations

- Optional remote access

- More than seven languages available

- Detailed documentation of measurement data, reports, etc.

- Easy settings adjustment, incl. password-protected, multi-stage user

management - Export function for measurement data and reports

- Alarm history

- All the important values are displayed

What are your requirements?

Talk to our competent contacts and discover the advantages and possibilities for your application. We analyse, advise and supply swift and suitable solutions. We look forward to hearing from you.