ActiCo – activated carbon filters

APROVIS ActiCo

Effective gas purification through activated carbon filters

APROVIS ActiCo activated carbon filters are used when gases are contaminated with hydrogen sulphide (H2S), siloxanes or other substances. This is the case, for example, with biogas, sewage gas or landfill gas. The ActiCo reliably removes these pollutants from the process gas for further use in combined heat and power plants or biogas treatment plants. The hydrogen sulphide must be separated so the combined heat and power plant can be operated with an exhaust gas catalytic converter. This gas purification reduces the plant’s downtimes and increases operational reliability. With its comprehensive range of services, as an innovative technology company APROVIS thus significantly optimises CHP plants’ combustion process.

What you can expect with an APROVIS ActiCo:

- Careful gas purification

- Reduction of emissions

- Damage prevention

- Higher operational reliability

- An improved combustion process

- An extended activated carbon service life

Activated carbon’s important job

The process of adsorption is necessary to desulphurise the process gas and separate siloxanes. The hydrogen sulphide contained in the gas is converted into elemental sulphur by a physical / chemical process. This accumulates on the porous surface of the ActiCo system’s specially treated activated carbon. Siloxanes are removed based on a physical process.

All components that come into contact with media are made of high-quality stainless steel (316L or equivalent), which ensures that the ActiCo systems have a long service life.

The important function of gas purification

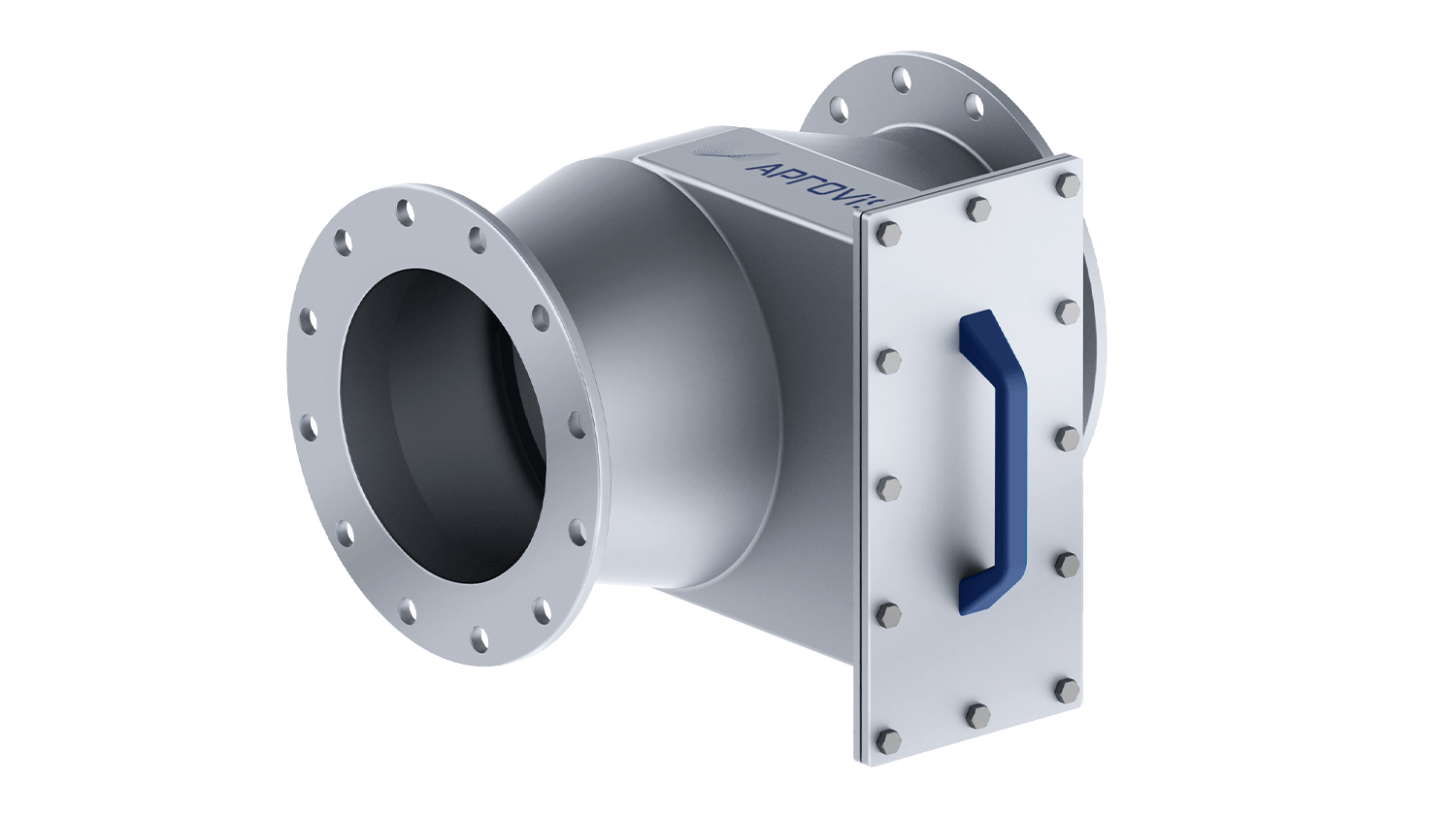

ActiCo-Mini for very small quantities of gas

The ActiCo-Mini is the name of the compact version for very small quantities of gas (max. 70 Nm3 /h). It is an affordable variant that works with about 60 kg of activated carbon. ActiCo-Mini is particularly suitable in the sewage gas sector. A perforated base in the container ensures optimum flow distribution through the activated carbon filling. The loaded activated carbon is removed from the container through the opening in the side. Filling is carried out with a Big Bag through the filling opening on the lid.

What the APROVIS ActiCo-Mini has to offer:

- Single-chamber variant

- 1 measuring nozzle for monitoring pollutants in the container

- Inertisation nozzle

- Insulated activated carbon container

- 2 threaded flange flaps for gas inlet and outlet

- Initial filling with doped activated carbon

- Filling from above; drainage from the side

- Additional options are possible

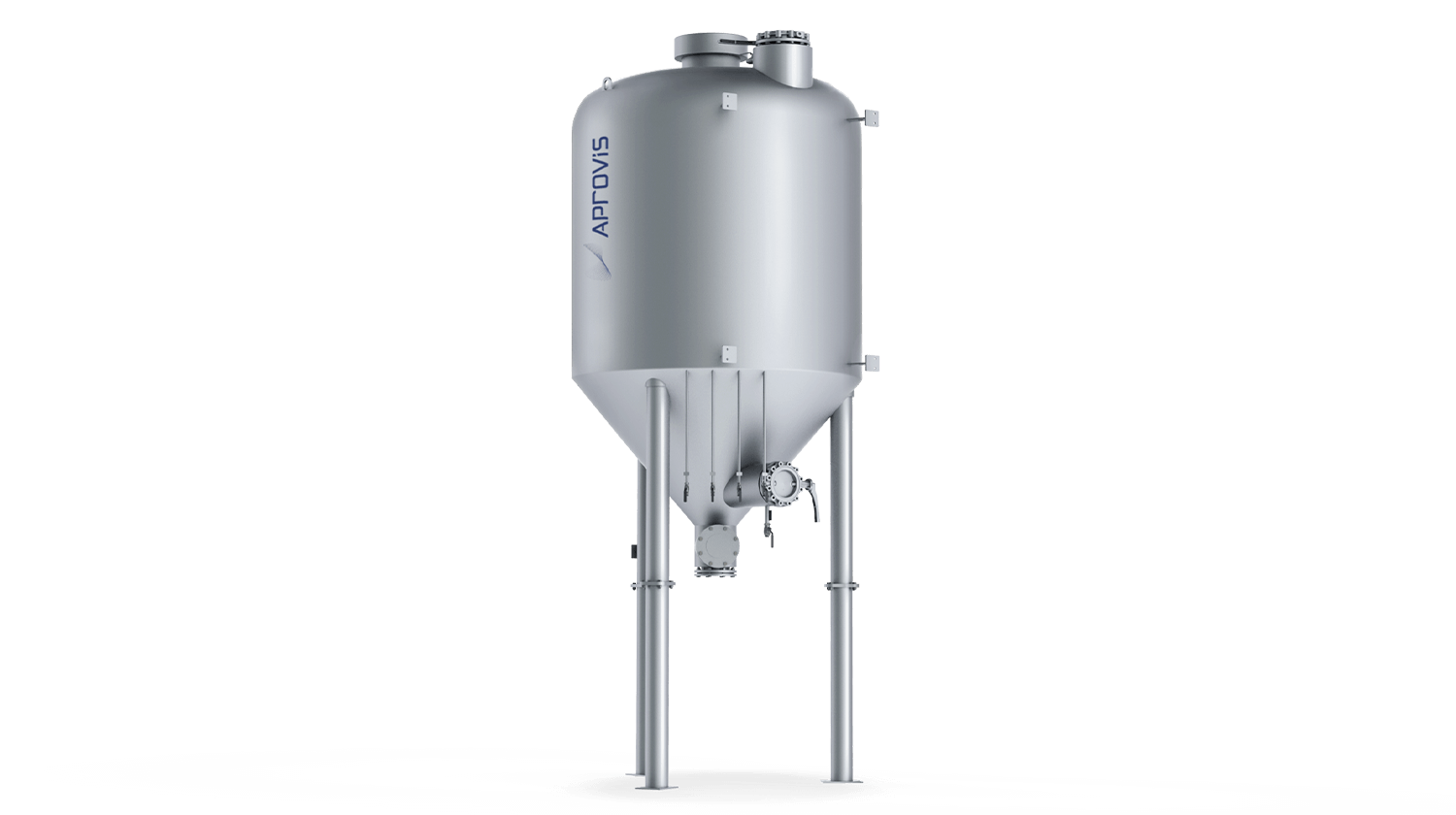

ActiCo-Basic for quantities of gas from 80 Nm³/h

What the APROVIS ActiCo-Basic has to offer:

- Single-chamber variant

- 3 measuring nozzles for monitoring pollutants in the container

- Inertisation nozzle

- 2 threaded flange flaps for gas inlet and outlet

- Initial filling with doped activated carbon

- Filling from above; drainage from the side

- Insulated activated carbon container

- Additional options are possible

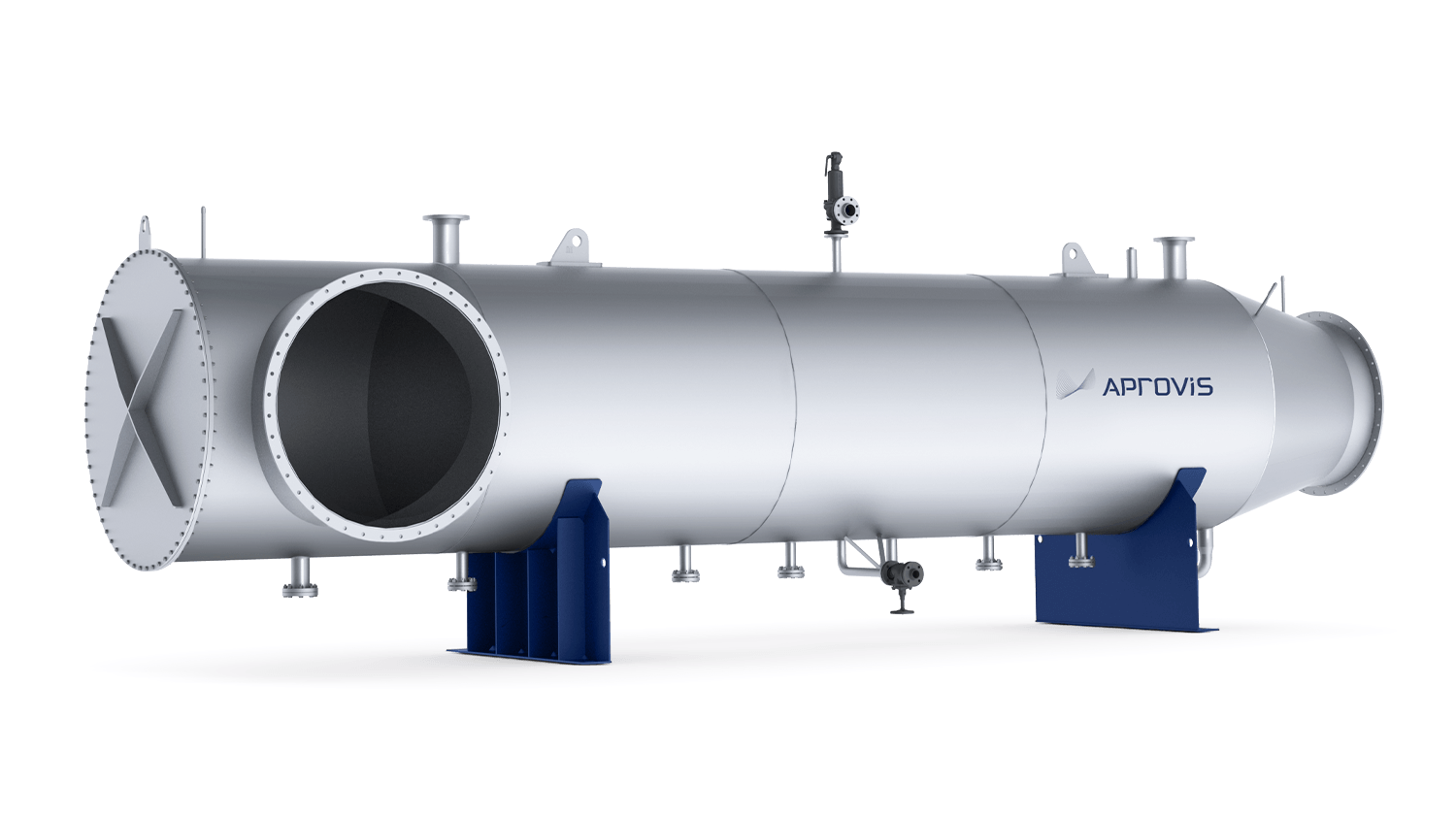

ActiCo-Pro for quantities of gas from 80 Nm³/h with a dual-chamber system

What the APROVIS ActiCo-Pro has to offer:

- Dual-chamber variant

- 4 measuring nozzles for monitoring pollutants in the container

- 2 inertisation nozzles with shut-off ball valves and screw plugs

- 2 threaded flange flaps for gas inlet and outlet

- Gas-tight 2-in-1 multi-slider (slide valve) for drainage

- Initial filling with doped activated carbon

- Filling from above; drainage from below

- Insulated activated carbon container

- Additional options are possible: e.g. service platform, lifting device for activated carbon

ActiCo-ProDuo with convenient lifting device for filling

This is the most user-friendly variant of the ActiCo family. Similar to the ActiCo-Pro, the ActiCo-ProDuo can also be operated as a dual-chamber system with a 2-in-1 multi-slider integrated gas-tight in the container in conjunction with the measuring connections and the custom option. This makes full use of the activated carbon’s loading capacity, and unloaded activated carbon does not have to be disposed of. A lifting device firmly assembled on the activated carbon filter is used to fill the activated carbon container. A service platform with ladder makes operation easier and increases health and safety.

What the APROVIS ActiCo-ProDuo has to offer:

- Dual-chamber variant

- 4 measuring nozzles for monitoring hydrogen sulphide in the container

- 2 inertisation nozzles with shut-off ball valves and screw plugs

- 2 threaded flange flaps for gas inlet and outlet

- Gas-tight 2-in-1 multi-slider (slide valve) for drainage

- Initial filling with doped activated carbon

- Service platform with ladder

- Convenient lifting device for filling the activated carbon

- Filling from above; drainage from below

- Insulated activated carbon container

Customised and system-specific options for the ActiCo

For all the ActiCo models listed above, being an industry expert APROVIS also supplies additional options. An example from our range of services:

- Flex heater: The Flex heater keeps the ActiCo container at temperature when there is no continuous flow through it. This helps to prevent condensation of moisture and thus a negative influence on the activated carbon. Heating is carried out using hot water. If hot water is not available at the biogas plant, APROVIS can also provide a suitable solution.

Additional highlights and functions of the ActiCo systems from APROVIS:

- Pollutant breakthrough can be determined directly with a gas analyser via the measuring connection. Alternatively, a gas sample can be taken and analysed in the lab.

What are your requirements?

Talk to our competent contacts and discover the advantages and possibilities for your application. We analyse, advise and supply swift and suitable solutions. We look forward to hearing from you.