FriCon – gas treatment

APROVIS FriCon

Gas treatment at the highest level

The FriCon system cools and dehumidifies process gases for further use in combined heat and power plants or biogas treatment plants. This optimises the combustion process and increases operational reliability. Plant downtimes can also be reduced. By cooling the gas stream, the moisture it contains condenses and can be removed from the gas and discharged as condensate. The equipment, featuring an optional demister, removes up to 99% of the condensate droplets. FriCon systems from APROVIS are manufactured to be permanently and technically tight and prepare the gas for further purification steps. Generally speaking, expert gas treatment by APROVIS does not require any supply other than a gas line and electricity connection.

What you can expect with an APROVIS FriCon:

- FriCon systems are ready for connection

- The FriCon removes the moisture from the process gas by dropping below the dew point temperature

- FriCon gas heat exchangers operate at elevated pressure, ambient pressure and negative pressure

- Condensate formation in downstream gas lines is avoided

- Suspended matter is separated

- The FriCon is available in different sizes and designs

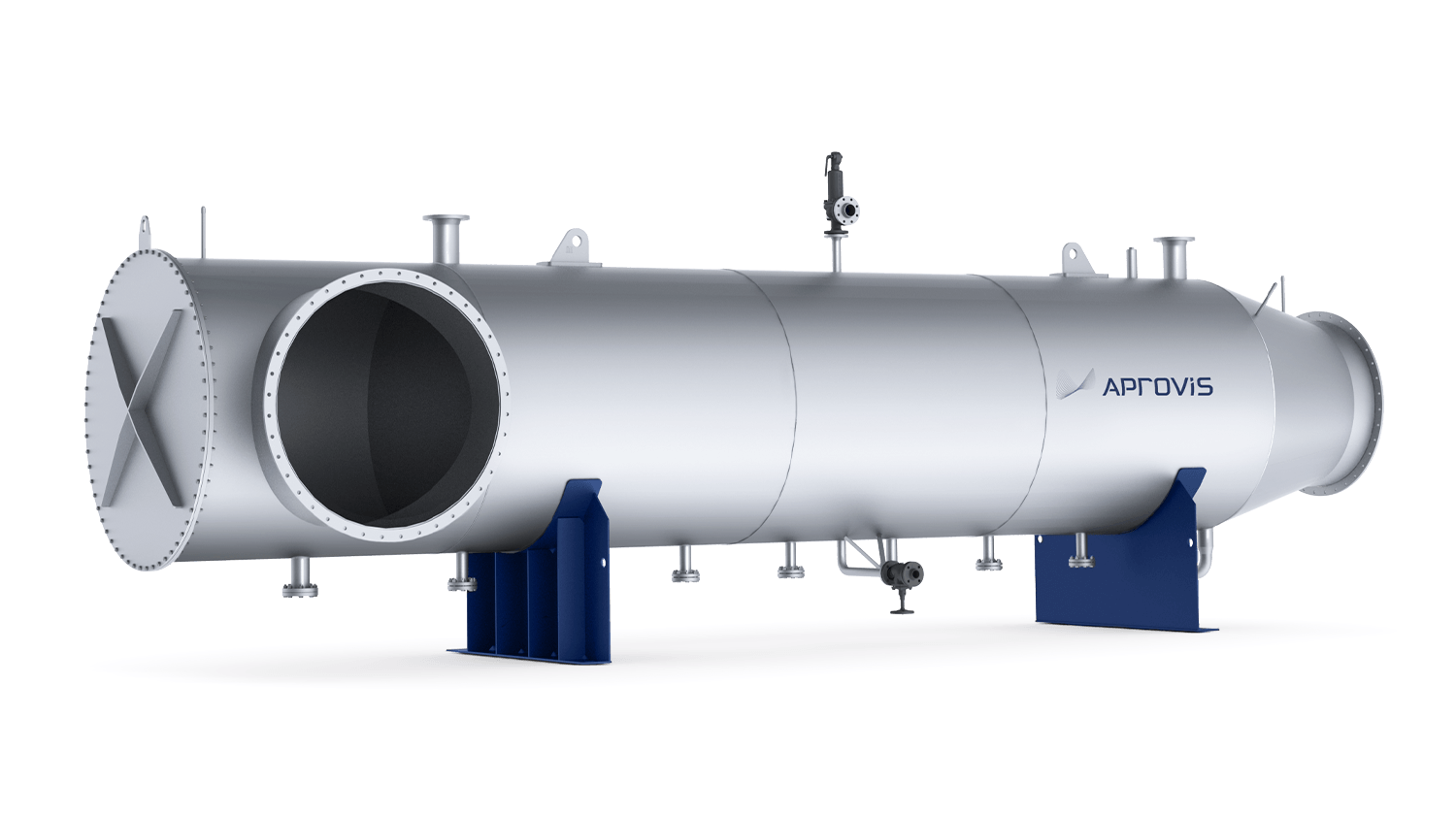

Gas dehumidification and gas cooling in a single circuit

The process gas is dehumidified according to the condensation drying principle. Water-cooled shell-and-tube heat exchangers are used for this purpose. When the gas stream cools down, the moisture condenses and can then be removed from the process. If condensate forms during the cooling process, it is collected in a condensate collection vessel while the level is monitored. A condensate pump discharges the condensate. Once it is cooled, the gas can be passed through a demister as an option. Up to 99% of the condensate droplets are caught on the wire mesh pack (demister). All components that come into contact with media are made of high-quality stainless steel (316L or equivalent), which ensures that the FriCon system has a long service life.

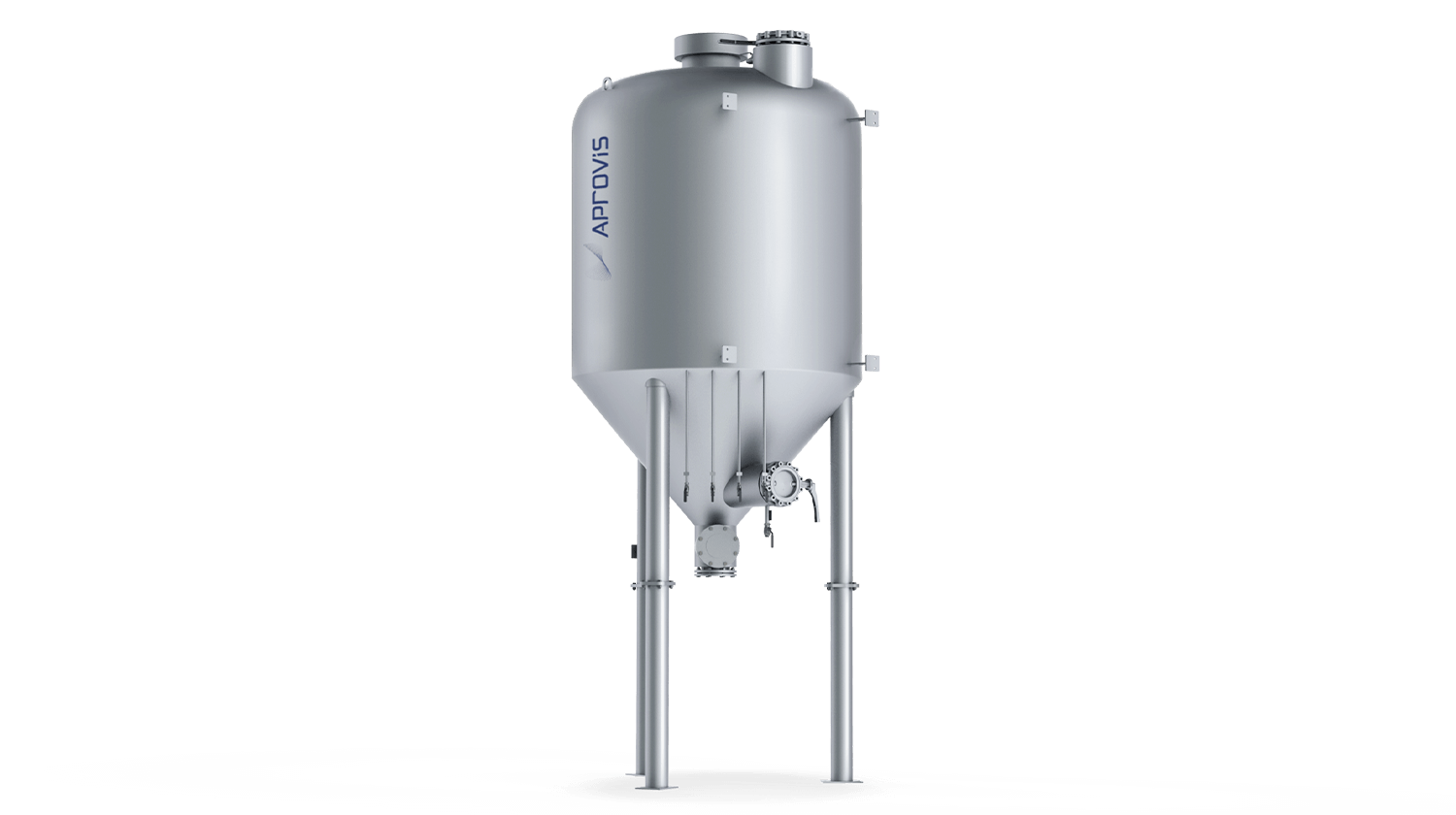

FriConBASIC – a solid basic model

FriConBASIC is the practical and most affordable version of the FriCon systems. A controller is not provided for, or only to a limited extent. A chiller with an integrated hydraulic module provides and circulates the required coolant. The system controller regulates the cold water temperature and monitors operating data. A buffer tank ensures that the chiller does not cycle too frequently in partial load mode, which extends the unit’s service life.

What the APROVIS FriConBASIC has to offer:

- Gas cooler (= gas heat exchanger)

- Chiller, EUROVENT-certified

- Base frame

- Insulation of the cooling components (vapour diffusion-tight insulation with galvanised sheet metal)

- Demister

- Syphon

- Pipe trace heating against condensate freezing (e.g. in the syphon)

- Water / glycol initial filling (34% by volume)

FriCon with customer-friendly operation

The FriCon is the user-friendly version of the FriCon systems. Unlike the FriConBASIC, the FriCon offers convenient regulation and control. The FriCon is supplemented by a condensate collection vessel with a condensate pump. Otherwise, FriCon offers the same advantages and functions as the FriConBASIC.

What the APROVIS FriCon has to offer:

- Gas cooler (= gas heat exchanger)

- Chiller, EUROVENT-certified

- Base frame

- Insulation of the cooling components (vapour diffusion-tight insulation with galvanised sheet metal)

- Demister

- Condensate collection vessel with pump

- Syphon (as an alternative to the condensate collection vessel)

- Pipe trace heating against condensate freezing (e.g. in the condensate collection vessel or syphon)

- Convenient regulation and control

- Water / glycol initial filling (34% by volume)

FriConPLUS with effective gas cooling and heating

The FriConPLUS is a user-friendly version of the FriCon systems and features convenient regulation and control. In addition, the FriConPLUS offers an integrated gas-gas heat exchanger to cool the incoming gas stream in an energy-saving manner. As with the other FriCon systems, a chiller with an integrated hydraulic module provides and circulates the required coolant. With the FriConPLUS, the gas’ relative humidity is adjusted by subsequent reheating. This is to prevent condensate (some of which is aggressive) from precipitating in the downstream sections of the plant. The gas is heated in a recuperator (gas-gas heat exchanger). This uses the heat of the incoming raw gas stream. The incoming gas stream is pre-cooled and the outgoing gas stream is heated, which significantly minimises the overall operating costs.

What the APROVIS FriConPLUS has to offer:

- Gas cooler

- Recuperator

- Chiller, EUROVENT-certified

- Base frame

- Insulation of the cooling components (vapour diffusion-tight insulation with galvanised sheet metal)

- Demister

- Condensate collection vessel with pump

- Syphon (as an alternative to the condensate collection vessel)

- Pipe trace heating against condensate freezing (e.g. in the condensate collection vessel or syphon)

- Convenient regulation and control

- Water / glycol initial filling (34% by volume)

FriConAIR for the highest gas treatment demands

The FriConAIR is a user-friendly and the most energy-efficient version of the FriCon systems designed to meet professional requirements. The FriConAIR offers convenient regulation and control. Additionally, it provides energy-saving cooling against the ambient air. It is used at gas inlet temperatures of > 40°C. The FriConAIR is often used in combination with the FriCon: high gas temperatures can be cooled with the FriConAIR, and lower gas temperatures with the FriCon. This saves energy in the chiller and less refrigeration capacity is required. It also permits the use of smaller chillers. A dry cooler with an integrated hydraulic module provides and circulates the required coolant. The system controller regulates the cold water temperature and monitors the operating data.

What the APROVIS FriConAIR has to offer:

- Gas cooler

- Liquid chiller

- Base frame

- Condensate collection vessel with pump

- Convenient regulation and control

- Water / glycol initial filling (34% by volume)

Customised and system-specific options for the FriCon

For all the FriCon models listed above, being an industry expert APROVIS also supplies solutions designed for extremely specific applications. Examples from our range of services:

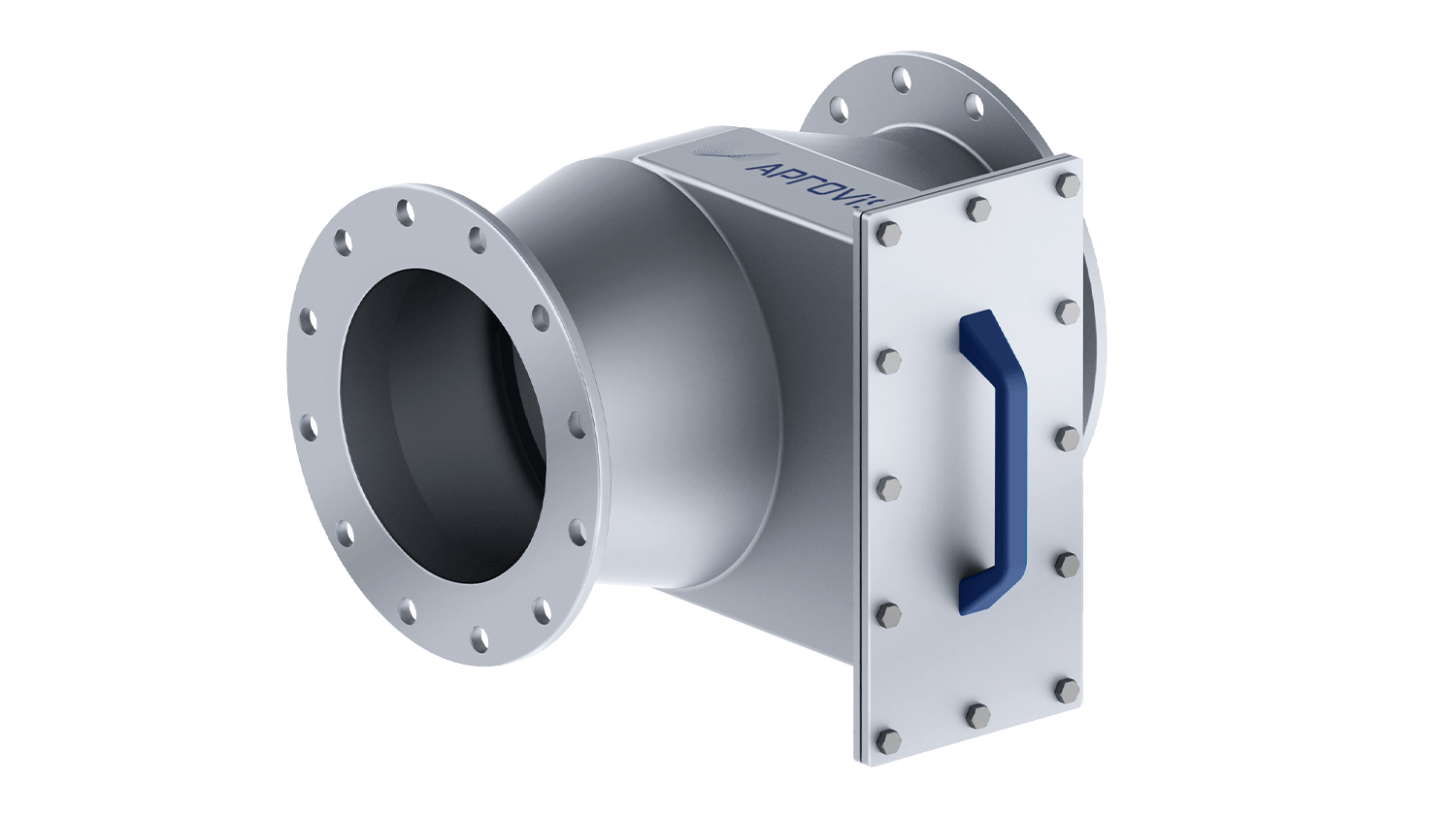

- Gas heater: The gas heater is used to avoid condensation in the downstream piping and/or when a certain relative humidity is required for optimum activated carbon functionality. If the biogas comes from the FriCon with 100% gas humidity, condensate or water renders the activated carbon unusable. Heating the biogas sets the appropriate gas humidity for the activated carbon. If hot water is not available at the biogas plant, APROVIS can also provide a suitable solution.

- Gas compressor: Gas compressors are required to transport the biogas. With a single or redundant design, the gas compressors ensure a constant flow rate in the FriCon in conjunction with the APROVIS controller.

- Temperature and pressure measuring devices (e.g. maximum temperature limiter, minimum pressure limiter)

Additional highlights and functions of the FriCon systems from APROVIS:

- Production in compliance with the specifications set out by the German Technical and Scientific Association for Gas and Water (DVGW) on request

- FriCon systems are generally suitable for installation outdoors

- The FriCon system can be installed in a container if required

- The FriCon system can be commissioned by APROVIS technicians on site or remotely

Following gas dehumidification, hydrogen sulphide and siloxanes are separated by activated carbon in the APROVIS-ActiCo

What are your requirements?

Talk to our competent contacts and discover the advantages and possibilities for your application. We analyse, advise and supply swift and suitable solutions. We look forward to hearing from you.