Process gas heat exchanger

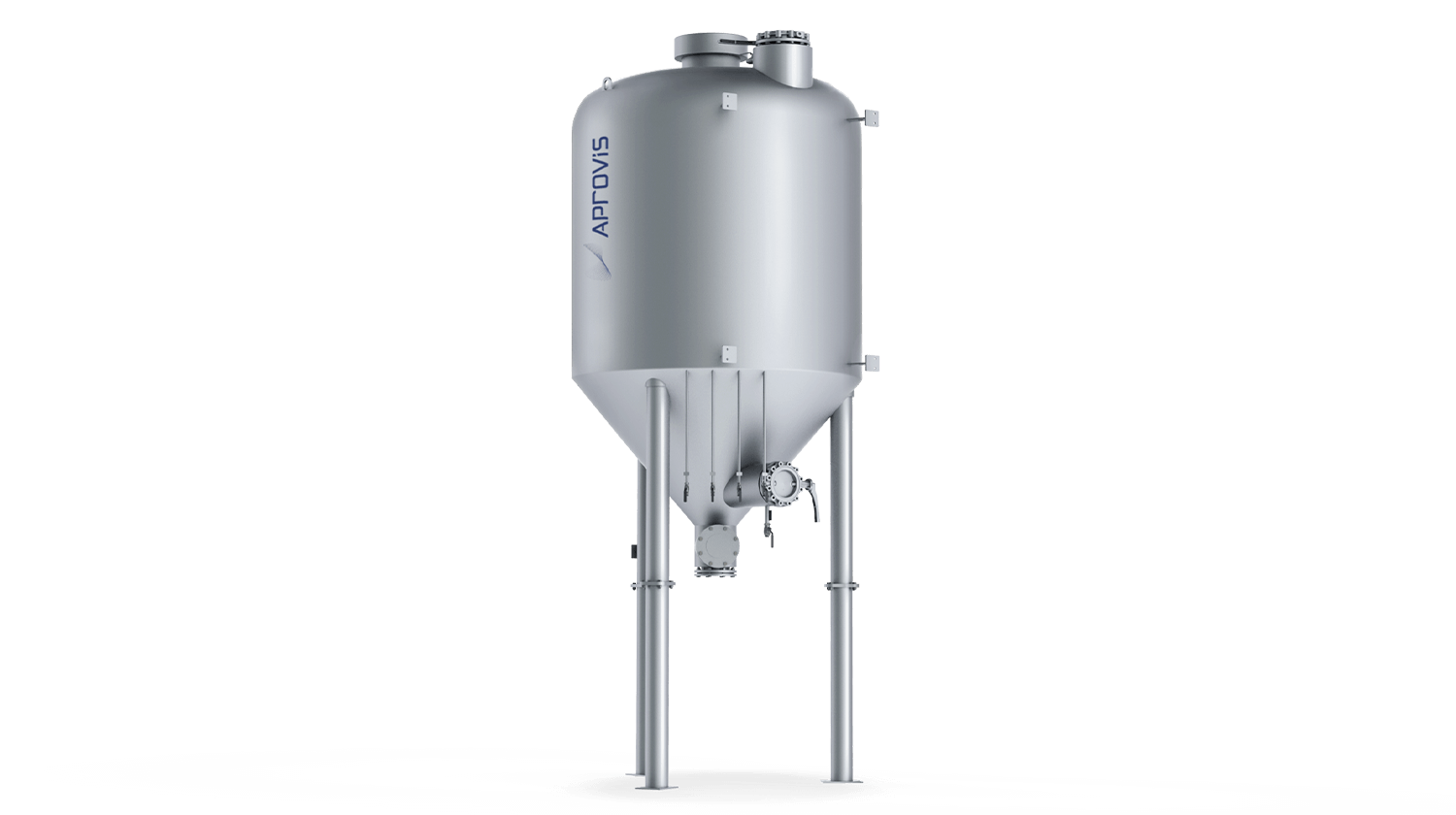

APROVIS process gas heat exchanger

An individual all-rounder for your gas applications

In many industrial processes and plants, gases have to be cooled or heated for further processing. Process gas heat exchangers from APROVIS can be used to accomplish these tasks.

Process gas heat exchangers are used in biogas plants, for example. Process gas heat exchangers offer the best solution for gas cooling in scenarios where the APROVIS FriCon complete cooling system cannot be used due to space restrictions or where a cooling source is already available on-site.

In addition, process gas heat exchangers play an important role in the further processing of biogas into biomethane. They are also used for cooling in gas compression plants and gas liquefaction plants and enable applications in many other areas.

Over 8,000 of these heat exchangers have been in operation across the globe for more than 20 years in a wide range of areas and applications.

What you can expect from an APROVIS process gas heat exchanger:

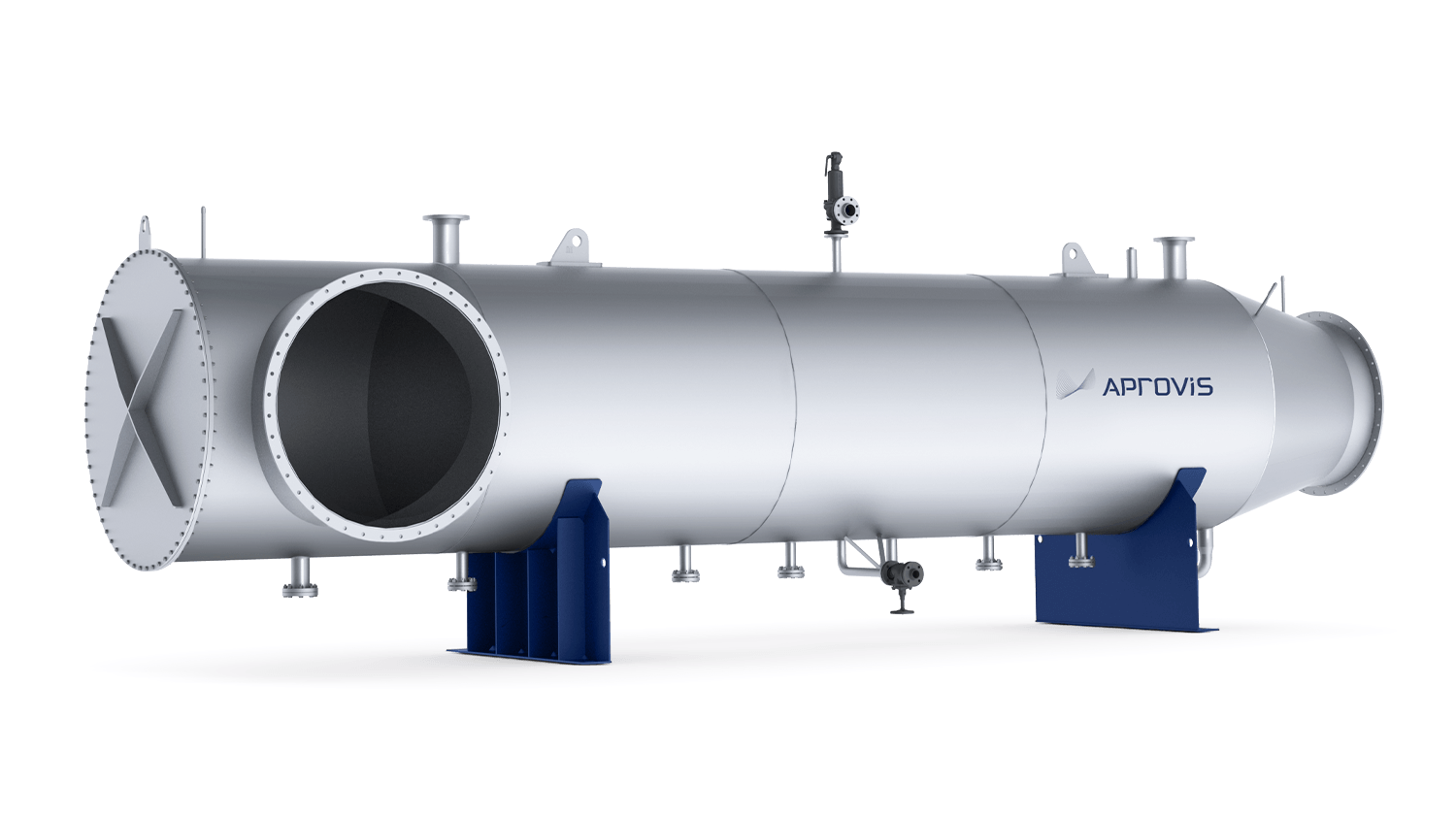

- Suitable for low and high temperature ranges

- Operating pressures up to 160 bar

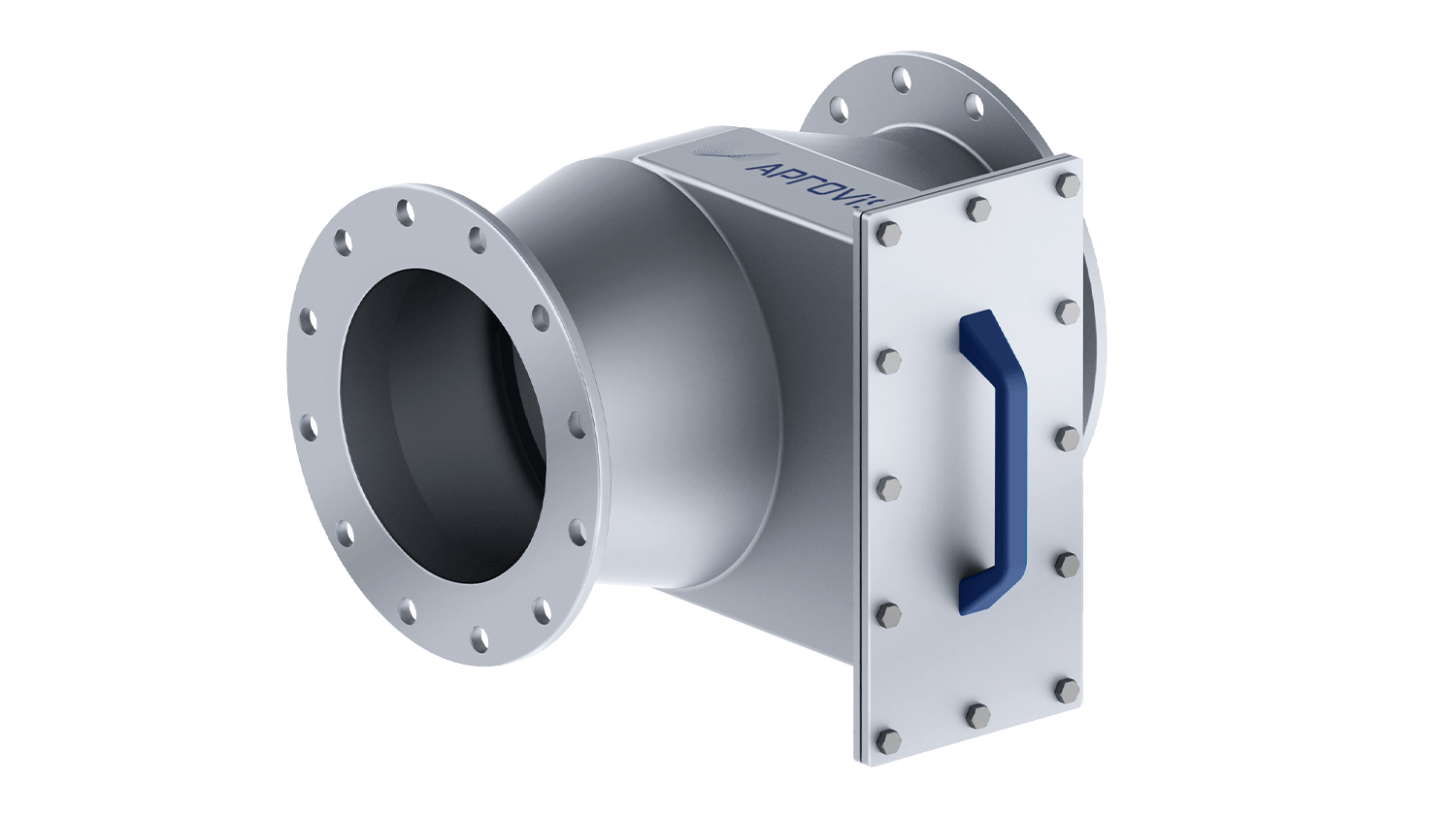

- Compact design for use in confined spaces

- Suitable for a wide range of gases

- Implementation of customised solutions

Heat recovery for energy saving

When gases are pressurised/compressed, they are heated to a very high temperature and require subsequent cooling before further processing. The heat needs to be dissipated and is ideally put to effective use by means of heat recovery. In this way, the energy can be channelled into the heating of other processes or fed into external heating grids. Compact process gas heat exchangers from APROVIS ensure that this heat transfer is optimised.

Potential applications of APROVIS process gas heat exchangers

- Gas cooling and gas dehumidification in biogas plants

- Heating of biogas prior to desulphurisation with activated carbon

- High-pressure heat exchangers in plants used to process biogas into biomethane and feed the natural gas grid

- Heat recovery with compressed air reservoirs

- Heat recovery with compressed air production plants

- Cooling and heating of inert gases for downstream processes

- Pyrolysis gas cooling

- Cooling of gases in gas compression plants and gas liquefaction plants

Additional highlights and functions of process gas heat exchangers from APROVIS:

- Optional inspection openings to facilitate cleaning for polluting gases

- Optional insulation for energy saving of heating or cooling energy

- Can be used worldwide thanks to certification in accordance with the European Pressure Equipment Directive, the ASME Code, EAC, and compliance with the specifications set out by the German Technical and Scientific Association for Gas and Water (DVGW)

- Demister for fine droplet separation

- Condensate collection vessel with and without a pump, with optional SIL components

Process gas heat exchangers combined with additional components

When used in combination with additional products from APROVIS, the gas line can be individually optimised – for example, with a FriCon (gas cooling system) or an ActiCo (activated carbon filter). APROVIS provides all the components and the know-how as an industry expert to help you cut project-related costs and save installation space.

What are your requirements?

Talk to our competent contacts and discover the advantages and possibilities for your application. We analyse, advise and supply swift and suitable solutions. We look forward to hearing from you.