SCR catalytic converters

APROVIS SCR catalytic converters

Systematic reduction in pollutant levels

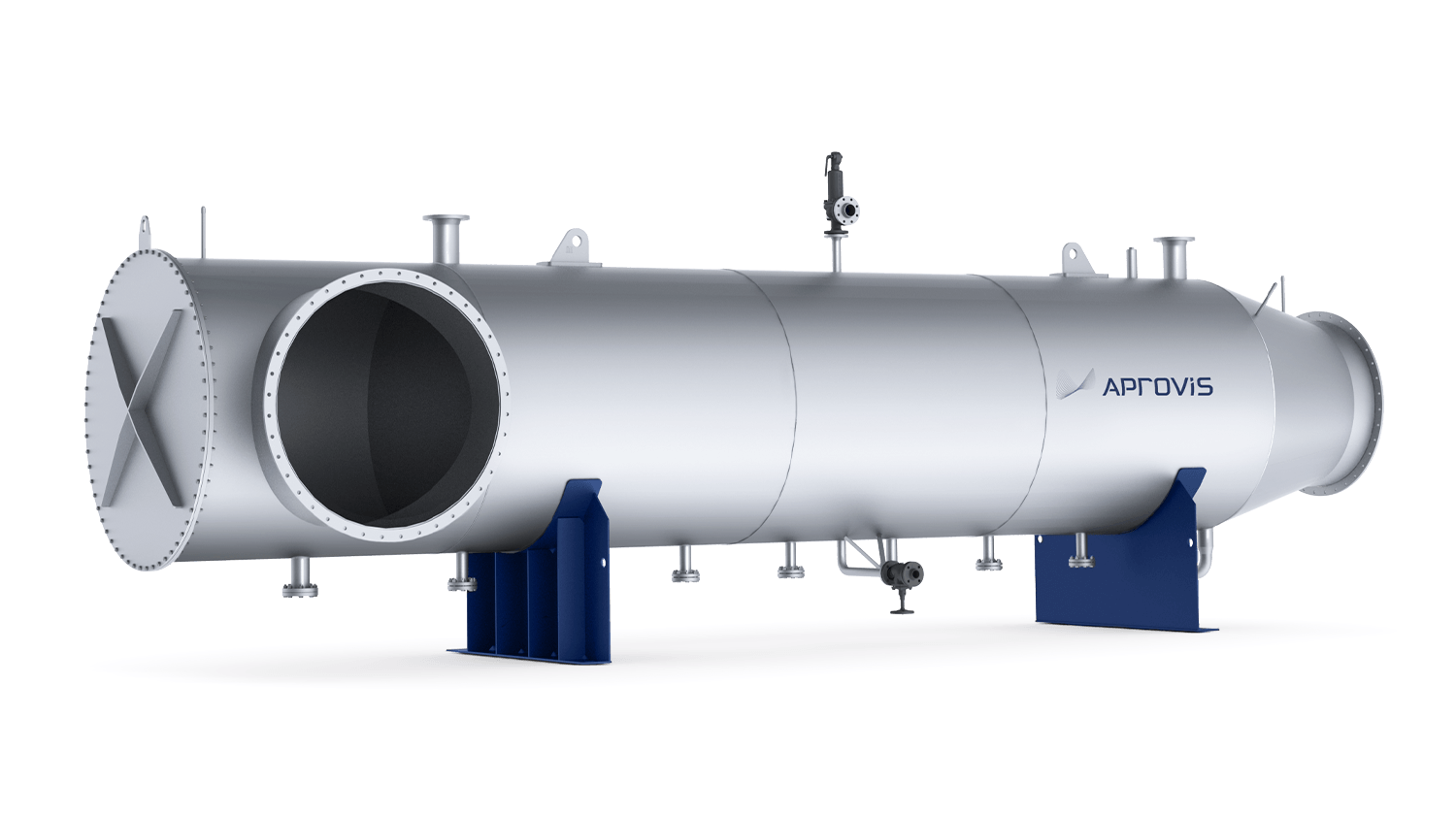

SCR catalytic converters perform the selective catalytic reduction of nitrogen oxides (NOx) from exhaust gases with the help of a reducing agent. The APROVIS Control System (ACS) ensures controlled and precisely coordinated dosing of the reducing agent and optimum mixing with the exhaust gas. Further reduction of carbon monoxide and/or formaldehyde is usually required. This is achieved by means of oxidation catalytic converters, which ideally can be integrated in the reactor housing alongside the SCR catalytic converters. APROVIS coordinates the catalytic converters with other components in the exhaust gas section to generate a high-performance system that runs reliably and reduces the impact on the environment as much as possible. APROVIS is the manufacturer of the entire product range, which keeps the necessary costs in check and still guarantees the best service.

What you can expect from APROVIS SCR catalytic converters:

- SCR housing with insulation

- Optimised design of the catalytic converter honeycombs

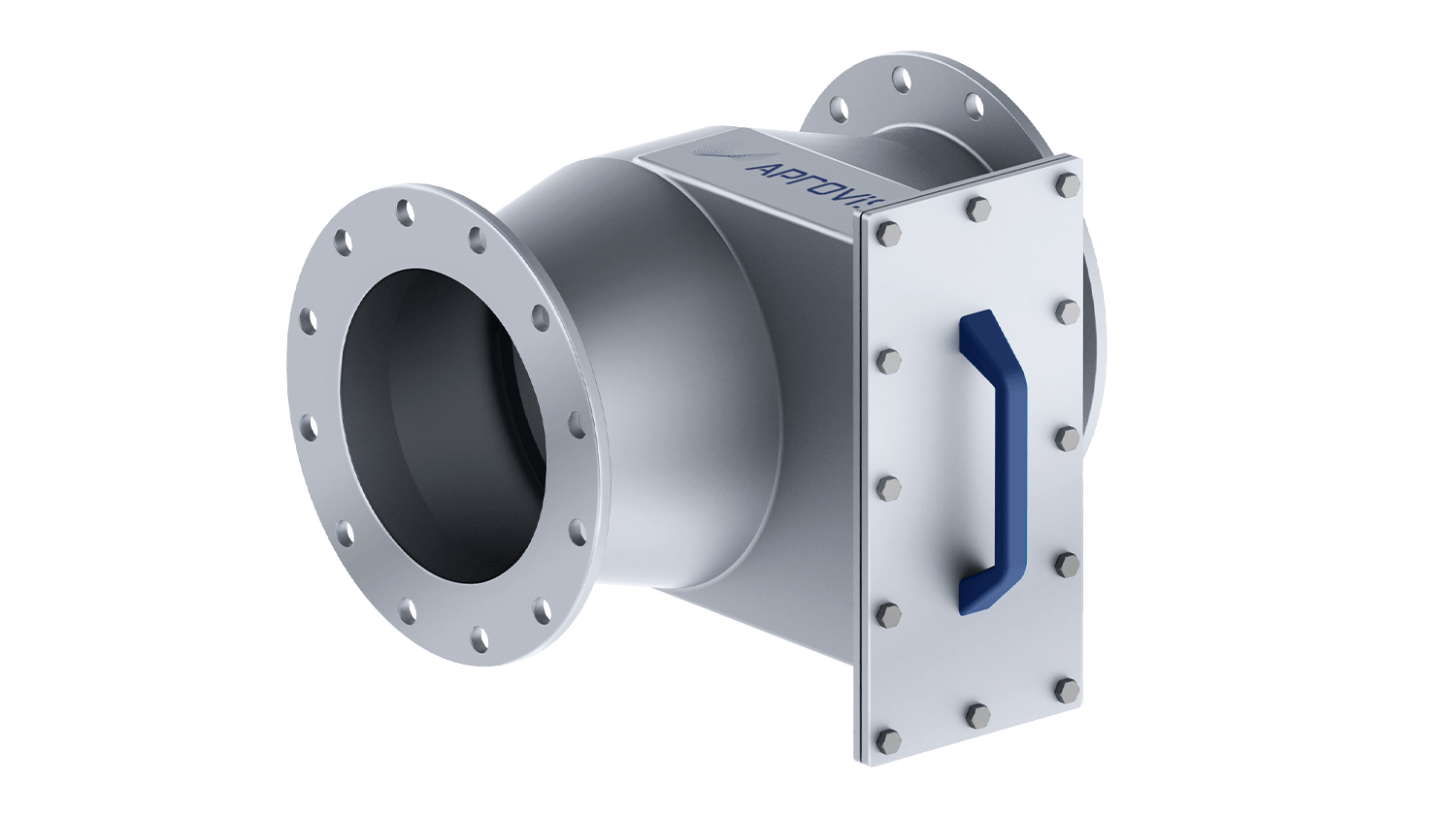

- Injection section with static mixers

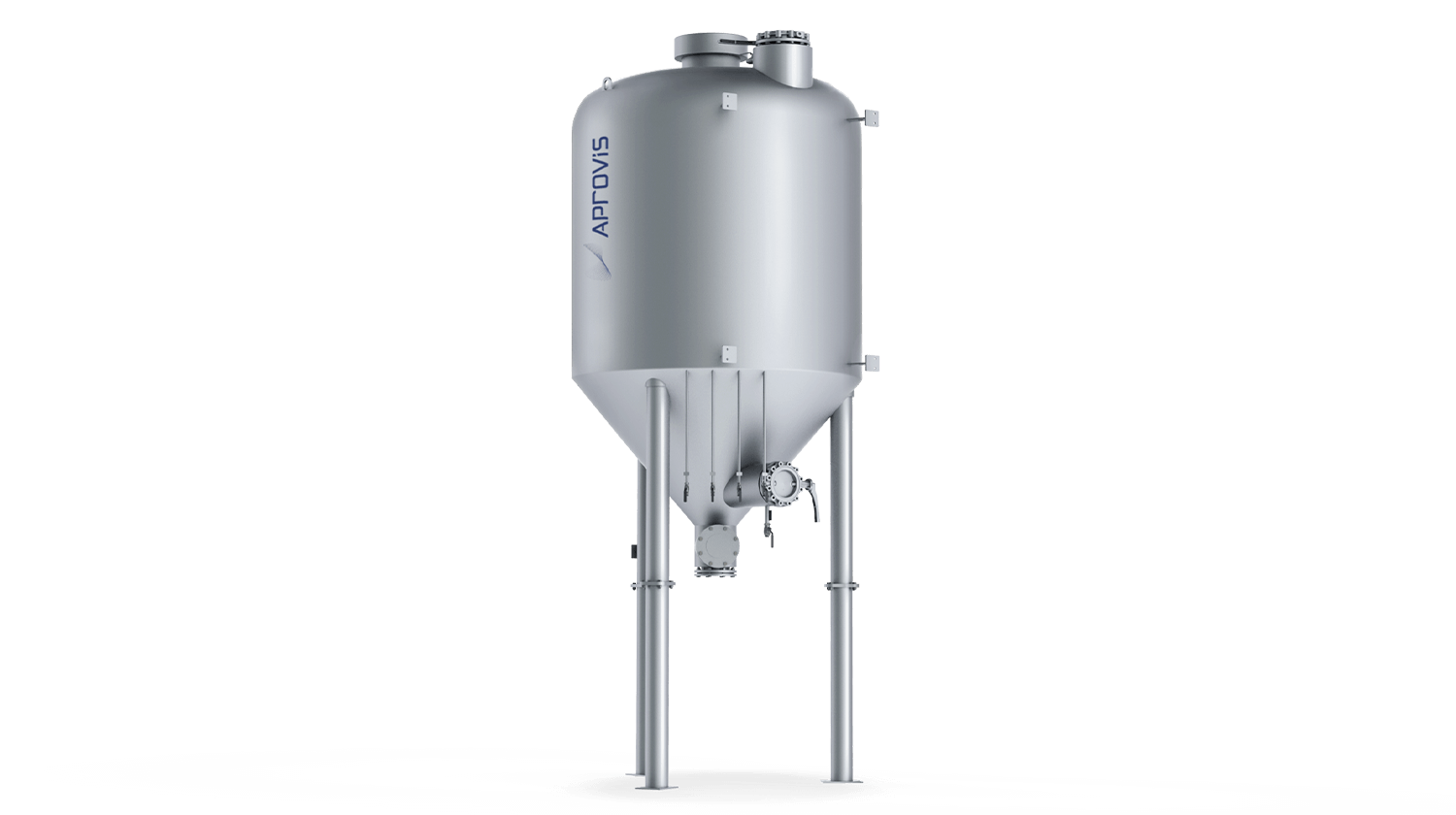

- Daily service tank

- Dosing station for exact dosing of the reducing agent

- Continuous measurement of nitrogen oxides (NOx)

- Controlled urea injection at measured NOx values

- High conversion rate and long service life

Reduce emissions by using a sound catalytic converter system

By adding the reducing agent (aqueous urea solution, AdBlue®) in the SCR catalytic converter, the nitrogen oxides (NOx) are selectively converted to nitrogen (N2) and water (H2O). SCR converts formaldehyde too. The integrated ammonia slip catalytic converter also reduces the amount of carbon monoxide and prevents ammonia from escaping. The APROVIS Control System (ACS) takes over the continuous monitoring of nitrogen oxides (NOx), which also saves the amount of reducing agent. The SCR dosing system injects the reducing agent from the daily service tank into the injection section through the nozzle lance. There, the urea in the exhaust gas is converted to ammonia, which is then mixed with the exhaust gas in the ideal ratio. Attention must be paid to the permissible limitation of the ammonia concentration (e.g. acc. to 44. BlmSchV, the Forty-Fourth Ordinance for the Implementation of the Federal Immission Control Act: 30 mg/Nm3 at 5% O2).

Additional highlights and functions of the SCR catalytic converters from APROVIS:

- Solutions also for gas and diesel engines in all performance classes of combined heat and power plant

- Individual design and selection of coatings

- Ceramic or metallic substrates are possible

Customer-friendly control of the SCR catalytic converter systems

The SCR catalytic converter’s scope of delivery includes a control box with a PLC control system; it is operated using a 10” touch panel (compliant with 44. BlmSchV and the VDMA 6299 standard sheet). This can be used to control the entire SCR system, and data recording is integrated. Data transfer over a communication bus (Modbus / Profibus) is available as an option, as is remote maintenance and remote monitoring to monitor and set operating parameters. This ensures economical and environmentally-friendly operation of the SCR catalytic converter system. Digitally supported remote commissioning can be carried out too.

Improved SCR catalytic converter performance thanks to supplementary components

The exhaust gas section can be optimised and customised by coordinating all the individual products. APROVIS supplies all the components (designed to be cost or installation space-optimised depending on requirements) from a single source for this purpose. The combination of an SCR catalytic converter and a silencer, for example, is a particularly compact solution. It saves on installation space, which is particularly advantageous if and when emission regulations are modified and exhaust gas aftertreatment has to be upgraded, for example in terms of pollutant emissions or sound insulation. What’s more, an optimised injection section in the reflective part of the silencer regulates the ideal mixing of exhaust gas and reducing agent.

Relevant environmental protection guidelines

The Forty-Fourth Ordinance for the Implementation of the Federal Immission Control Act (44. BlmSchV) is the national transposition of the European Directive for medium-sized combustion plants (Medium Combustion Plant Directive, MCPD). The aim is to reduce emissions of particulate matter, sulphur dioxide and nitrogen oxide. The 44. BlmSchV applies to operators of medium-sized combustion plants, i.e. plants with a capacity range of 1 to 50 MW of combustion heat, including gas turbine and combustion engine plants. This new directive is highly complex, and a wide variety of transition periods must be observed. For example, limits for existing or new systems or specifications as to the date by which retrofitting must be adhered to. APROVIS stands by its customers as a competent partner for any and all questions – from the planning stage and subsequently during ongoing plant operation.

What are your requirements?

Talk to our competent contacts and discover the advantages and possibilities for your application. We analyse, advise and supply swift and suitable solutions. We look forward to hearing from you.