APROVIS FriLava

APROVIS FriLava

Sustainable gas purification

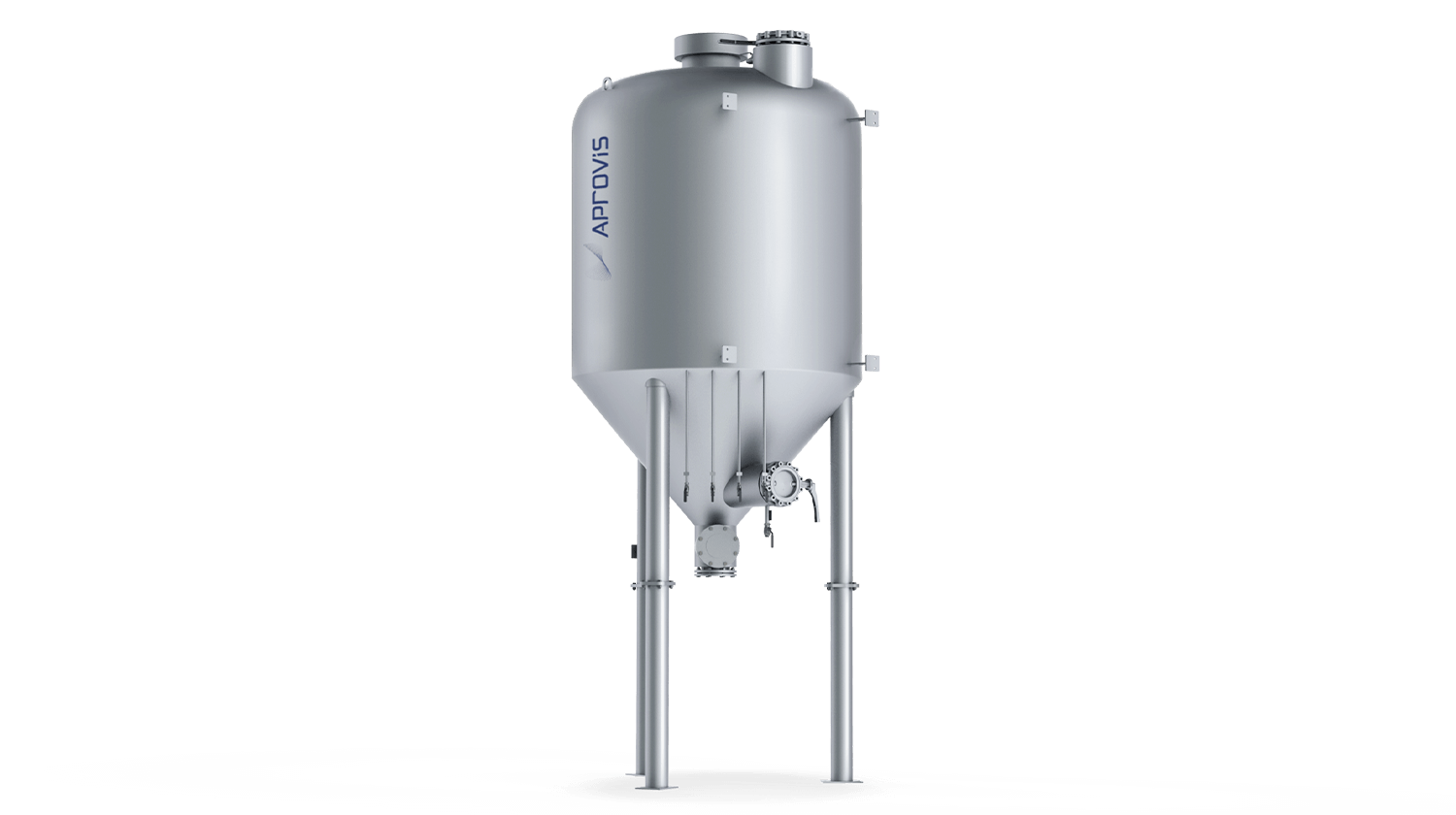

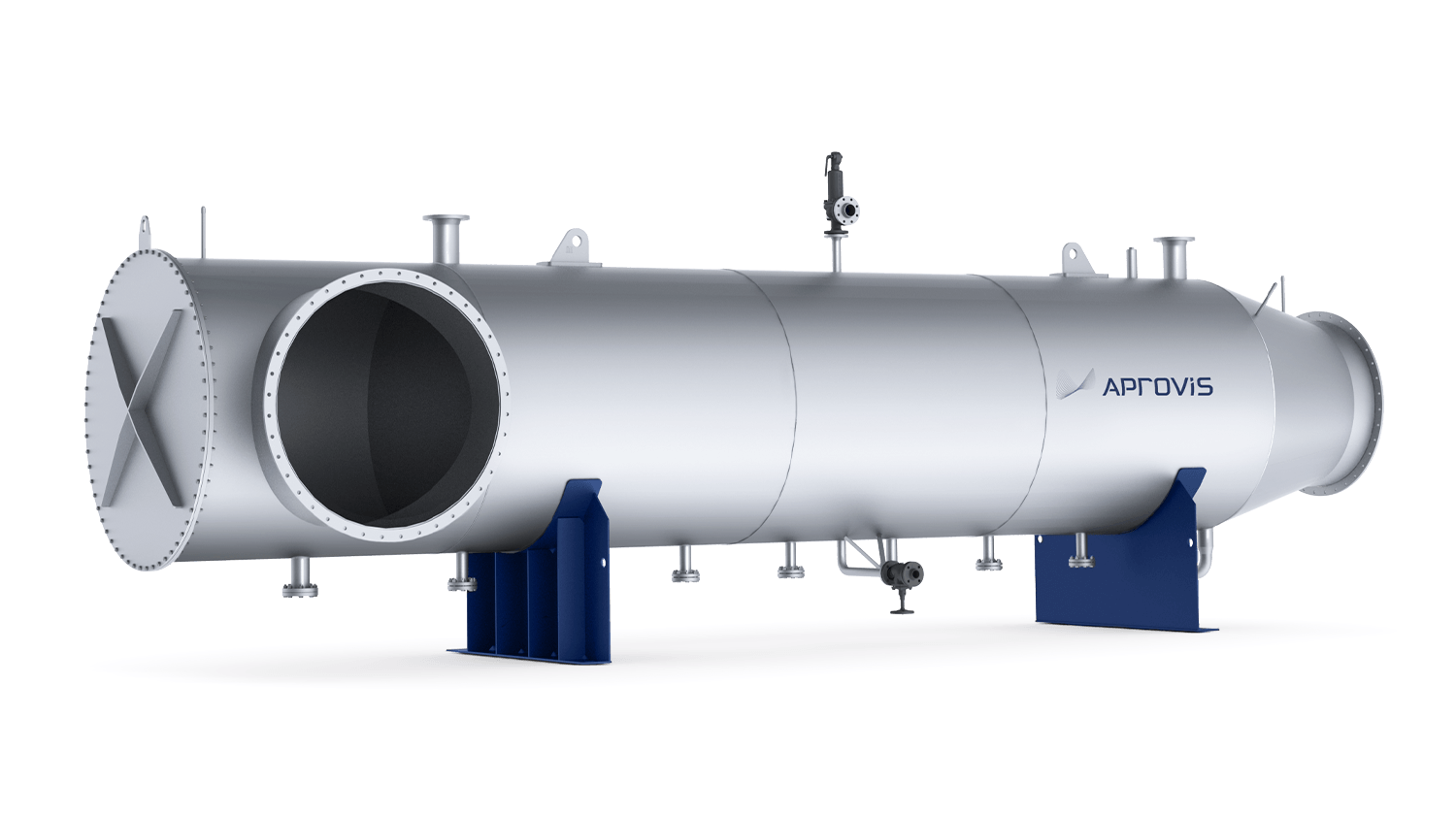

The FriLava scrubber with gas drying function scrubs and dries process gases for subsequent use in biogas treatment plants (biogas to biomethane) or in combined heat and power plants (CHP units). The main purpose of the FriLava is to remove ammonia and humidity from biogenic gases, usually biogas from fermentation processes as well as sewage gas.

Biogas can be burned directly in a CHP unit engine to generate electricity and heat. This combustion process is also more efficient without ammonia. Upgrading biogas to biomethane by removing CO2 is another important use of biogas. This can be done using various technical processes. Upgrading biogas to biomethane is becoming increasingly popular, as it can be fed into an existing natural gas grid to replace natural gas.

Advantages of ammonia-free biogas

Ammonia interferes with the upgrading of biogas to biomethane, for example, in pressure swing adsorption or membrane technology. The removal of ammonia from biogas is therefore a fundamental and necessary technological development. Scrubbing the biogas with cooled water also dries the biogas, causing it to fall below the dew point and produce condensate. The FriLava therefore cools and dehumidifies the biogas. The new condensate produced from the biogas is discharged from the process so that a constant amount of scrubbing water is always available.

When using the FriLava in gas purification, a FriCon is no longer required.

The FriLava therefore replaces the FriCon entirely.

What you can expect with an APROVIS FriLava:

- FriLava scrubbers with gas drying function are ready for connection

- The scrubbing process removes the ammonia content and solids almost completely

- The FriLava removes the humidity from the biogas by cooling the gas to below the dew point temperature

- Optimum treatment of the biogas for further purification steps (e.g. removal of hydrogen sulphide using activated carbon)

- Reduced system downtimes and increased operational safety

- Optimised combustion process of the CHP unit

Ammonia removal and gas dehumidification in one step

The gas is scrubbed and dried according to the scrubbing principle. A cooled stream of water is introduced contrary to the direction of flow, which runs over random packing to increase the surface area. Solids and trace gases are absorbed or physically bound by the water flow, depending on their water solubility. As the gas flow cools, the humidity contained in the gas condenses and is removed from the gas. Depending on the application, additional fresh water is required.

The resulting scrubbing condensate is discharged in a controlled manner. Alternatively, a condensate pump can be used to transport the condensate to more remote condensate collection points. Once cooled, the gas is fed through a demister. Up to 99% of the condensate droplets are caught on the wire mesh pack (demister). As all relevant components are made of high-quality stainless steel (1.4404 or equivalent), the FriLava system has a long service life.

What the APROVIS FriLava has to offer:

- Gas scrubber

- Chiller (EUROVENT-certified)

- Plate heat exchanger, pump and fittings

- Base frame

- Control box and wiring

- Insulation of the cooling components (insulation impermeable to vapour diffusion, encased in sheet metal)

- Trace heating to prevent condensate and scrubbing water from freezing

- Demister

- Water/glycol for initial filling

Customer and plant-specific options for the FriLava

As an industry expert, APROVIS also provides solutions for the FriLava that are designed for specific applications. Examples from our range of services:

- Gas heater: The gas heater is used to prevent condensation from forming in the downstream piping and/or when a certain relative humidity is required for optimum activated carbon functionality. If the biogas comes from the FriLava with 100% gas humidity, condensate or water renders the activated carbon unusable. Heating the biogas produces the right gas humidity for the activated carbon. If no warm water is available at the biogas plant, APROVIS can also provide a suitable solution.

- Gas compressor: Gas compressors are required to transport the biogas. As a single or redundant version, the gas compressors ensure a constant flow through the FriLava in conjunction with the APROVIS control system.

- Measuring instruments: Temperature sensors, temperature limiters, pressure sensors, pressure limiters, continuous oxygen measurement and volumetric flow rate measurements are available to provide data for comprehensive system monitoring.

Additional highlights and functions of the APROVIS FriLava systems:

- Production in compliance with the specifications set out by the German Technical and Scientific Association for Gas and Water (DVGW) and the German water resources act (WHG) on request

- FriLava systems are generally suitable for installation outdoors

- The FriLava system can be installed in a container

- The FriLava system can be commissioned by APROVIS technicians on site or remotely

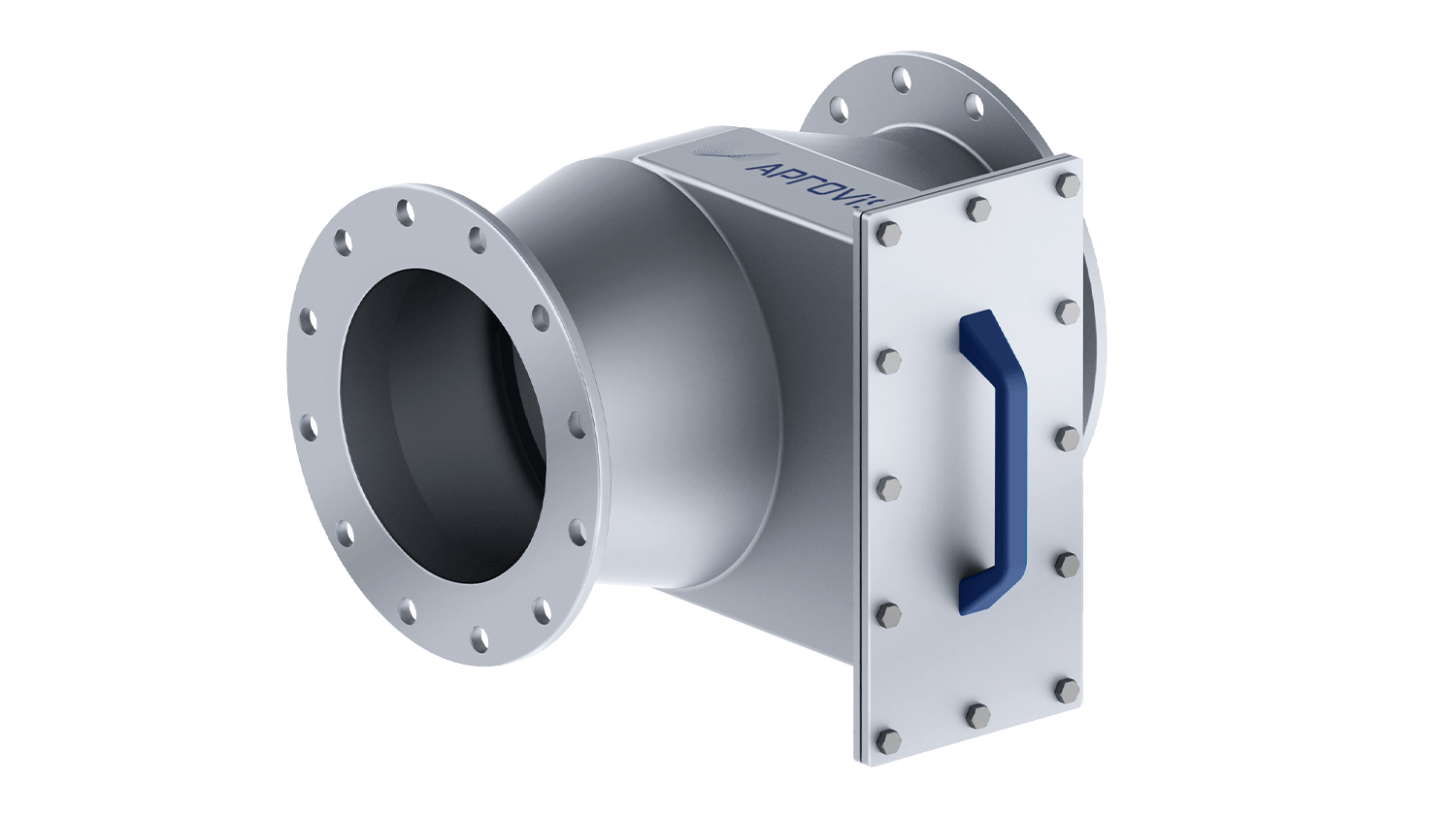

Following gas dehumidification, hydrogen sulphide and siloxanes are separated by activated carbon in the APROVIS ActiCo.

What are your requirements?

Talk to our competent contacts and discover the advantages and possibilities for your application. We analyse, advise and supply swift and suitable solutions. We look forward to hearing from you.