Oxidation and three-way catalytic converters

APROVIS oxidation and three-way catalytic converters

From exhaust gas to low-pollution air

When engines burn fuels, pollutants are formed in the exhaust gas. The catalytic converters from APROVIS take on the important task of significantly reducing the emission of such pollutants. APROVIS’s oxidation and three-way catalytic converters convert polluting components in the exhaust gas into harmless substances by oxidation. APROVIS – one of the leading technology companies in this field – also develops custom-made solutions for gas and diesel engines in combined heat and power plants.

Through standardisation and organised warehousing, APROVIS can offer extremely short delivery times. This applies to custom-made and series products, as well as to applications in mini combined heat and power plants or large engines. From the planning stage to ongoing operation of the catalytic converters, APROVIS remains a reliable contact for any questions you might have.

What you can expect from APROVIS oxidation and three-way catalytic converters:

- Individual design for each specific application

- Also special production for special applications

- Short delivery times

- Compliance with the limits over the warranty period

- Use of soldered metal supports to withstand high thermal and mechanical loads

- No telescoping of the catalytic converter elements

The oxidation and three-way catalytic converters’ cleaning performance

Oxidation catalytic converters (oxi-cats) reduce the amount of carbon monoxide, hydrocarbons and formaldehyde in the combustion exhaust gases. They use oxidation to convert gaseous pollutants into harmless substances (carbon dioxide (CO₂) and water (H₂O)). The resistance to sulphur is geared to the relevant operating conditions. In stoichiometric operation (lambda=1), a three-way catalytic converter can reduce carbon monoxide (CO), hydrocarbons and nitrogen oxides (NOₓ) in the exhaust gas. Nitrous oxides cannot be reduced with oxidation catalytic converters; APROVIS SCR catalytic converters are used for this purpose APROVIS-SCR-Katalysatoren.

A flexible system that adapts to demands

Installation in an exhaust gas heat exchanger’s inlet chamber is suitable for reducing emissions of carbon monoxide (CO) and formaldehyde with oxidation catalytic converters. This results in two major advantages: an additional housing is no longer needed, which saves on installation space, and the catalytic converter can be changed quickly. The same reasons apply to integration in a silencer. If there isn’t enough space for installation in one of these components, or if the type of exhaust gas routing does not allow it, a housing with a quick-change opening is the alternative. This makes servicing work a breeze and cuts operating costs. Three-way catalytic converters that have to be absolutely gas-tight are safe and easy to install between two flanges.

Installation variants for APROVIS oxidation and three-way catalytic converters

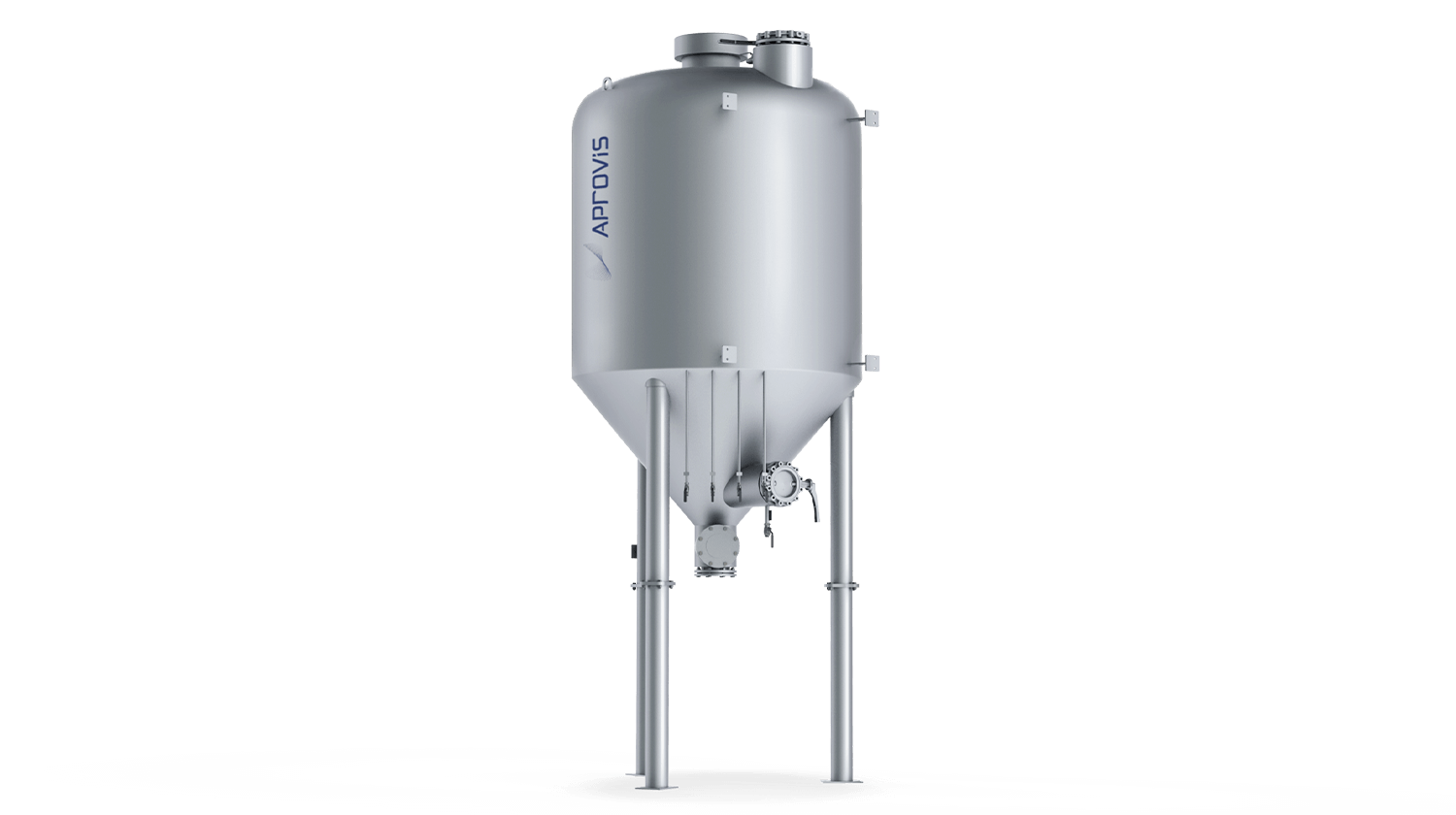

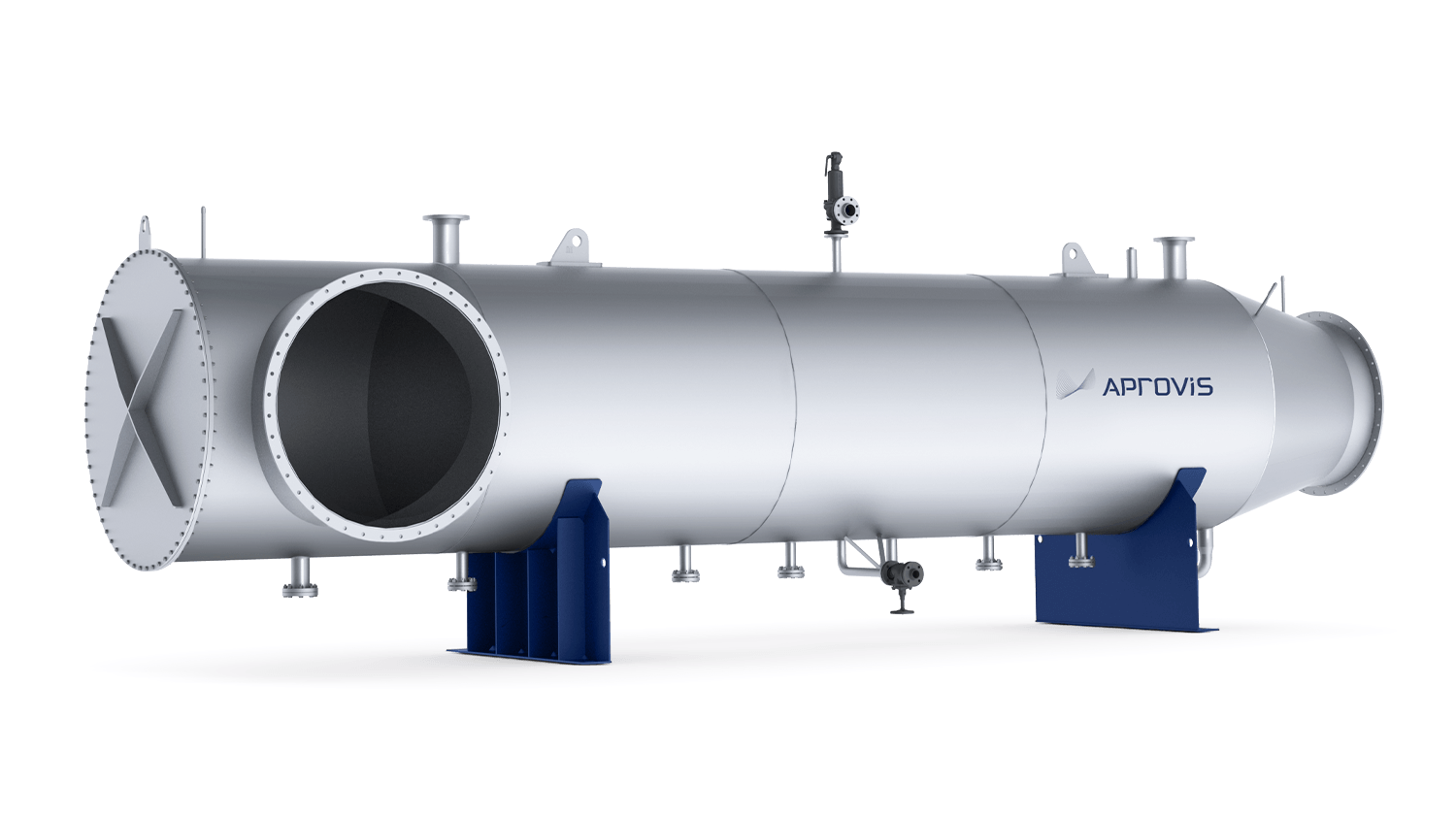

- Installation of oxidation catalytic converters in an exhaust gas heat exchanger’s inlet chamber

- Installation of oxidation catalytic converters in a silencer

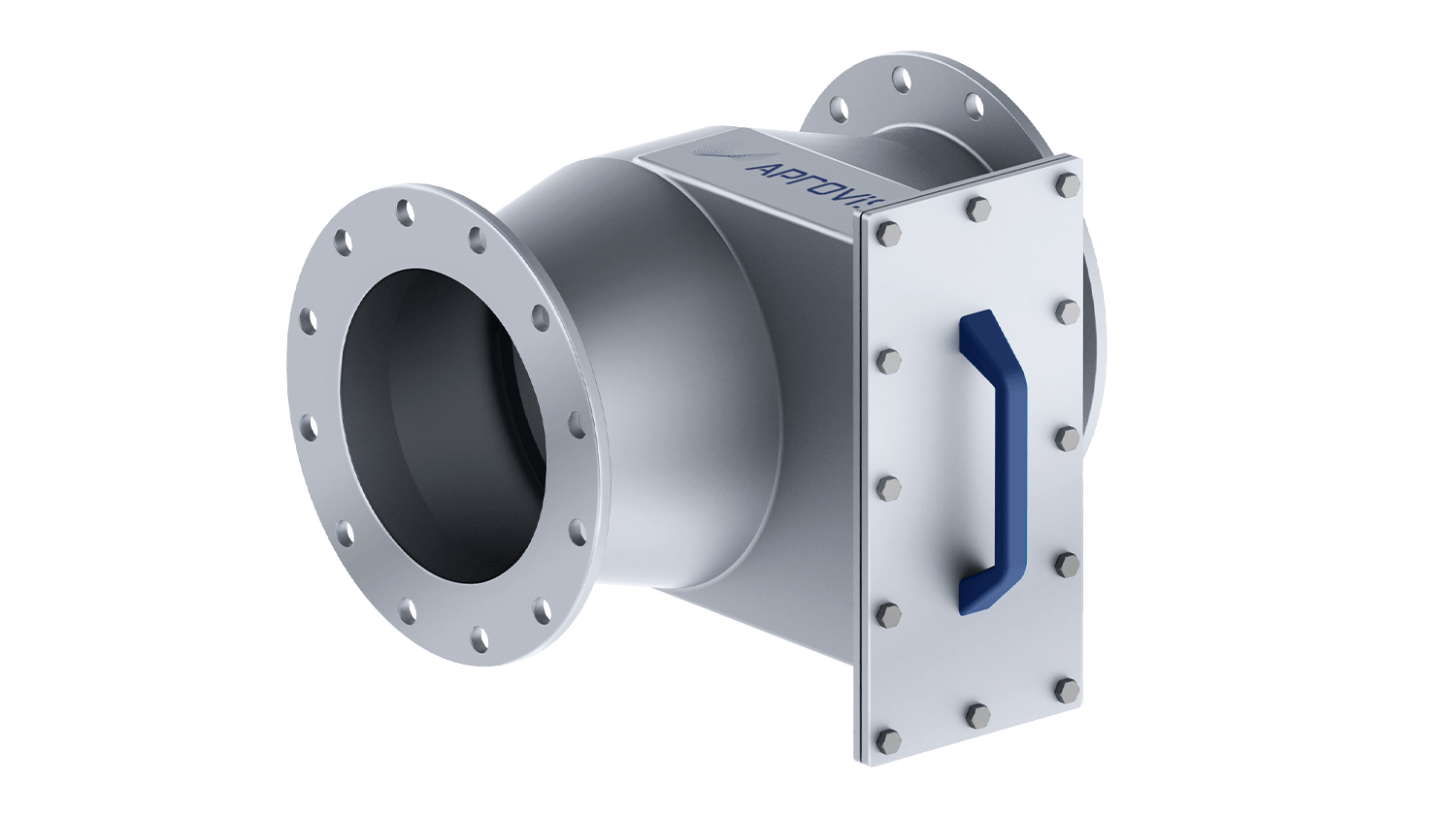

- Installation of oxidation catalytic converters in a housing with quick-change opening

- Installation for absolutely gas-tight three-way catalytic converters between two flanges

- Installation in combination with an SCR catalytic converter

Catalytic converters’ service life and recycling options

Regular cleaning of catalytic converters removes accumulated oil on the active surface, which extends the systems’ service life. APROVIS has developed an innovative recycling concept that makes recycling of used oxidation catalytic converters extremely lucrative for you as an operator. You send us your old catalytic converters (including those from other manufacturers) and receive remuneration for them that makes this worth your while.

Additional highlights for oxidation and three-way catalytic converters from APROVIS:

- Solutions also for gas and diesel engines in all performance classes of combined heat and power plant

- Individual design and selection of coatings

- Ceramic or metallic substrates are possible

What are your requirements?

Talk to our competent contacts and discover the advantages and possibilities for your application. We analyse, advise and supply swift and suitable solutions. We look forward to hearing from you.